Pieter Van Schalkwyk

CEO at XMPRO

Beyond Databases: Industrial AI Agents Need Both Records and Signals

Microsoft CEO Satya Nadella recently made a striking observation that marks a fundamental shift in enterprise software: business applications will collapse in the age of AI agents. He explained that today’s software applications are essentially “CRUD databases with business logic” – they store data and automate basic workflows. This simple but profound insight signals the end of traditional enterprise applications as we know them.

The shift to AI agents will transform how organizations work with their data and systems. Instead of humans interacting with applications that sit on top of databases, AI agents will directly access and act on information. As Foundation Capital notes, this represents a move from “software-as-a-service” to “service-as-software” where AI agents become the workers themselves rather than just tools for human workers.

This transformation goes beyond simply adding AI to existing applications. The business logic that currently lives in application layers will move into AI agents that can understand context, make decisions, and take actions across multiple systems. These agents won’t be limited by the rigid structures of traditional applications – they’ll work directly with data to accomplish business objectives.

However, in industrial settings, this transformation requires more than just replacing application layers with agents. While Nadella’s observation about databases and business logic captures an important truth about traditional enterprise software, the industrial world presents unique challenges that demand a more comprehensive approach.

As Geoffrey Moore points out in his work on data versus signals, there’s a critical distinction between verified facts stored in databases (records) and real-time operational data from sensors and systems (signals). This distinction is particularly important in industrial settings where success depends on understanding and making decisions on both historical patterns and current conditions.

Why Both Types of Data Matter

Consider a chemical processing plant running critical operations 24/7. The facility has decades of operational data stored in databases – maintenance records, procedures, quality logs, and incident reports. This historical information is valuable, but it’s not enough. The plant also generates thousands of real-time signals from temperature sensors, pressure gauges, flow meters, and quality monitors.

Effective industrial operations require both types of data:

- Historical records show what worked (and didn’t work) in the past

- Real-time signals reveal what’s happening right now

- Combined analysis enables better predictions about what might happen next

- Integrated responses help prevent problems before they occur

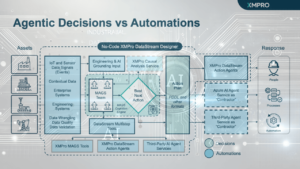

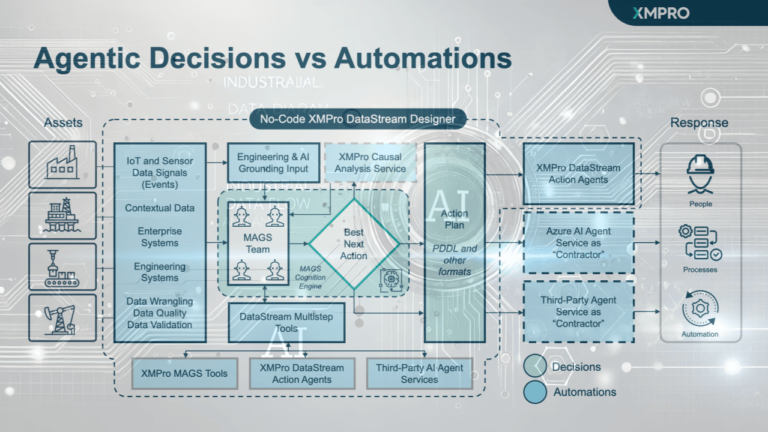

Going Beyond Workflow Automation

While many industrial AI solutions simply use LLMs to automate workflows, XMPro’s MAGS takes a fundamentally different approach. Our agents use an advanced memory cycle, similar to the military’s OODA (Observe, Orient, Decide, Act) loop, to make intelligent operational decisions. This process combines records and signals in each phase of decision-making.

Here’s how our agents process information to make better decisions:

- Observe: Agents continuously monitor both real-time signals from operations and access relevant historical records. This gives them a complete picture of what’s happening and its context.

- Reflect: The system analyzes current conditions against historical patterns, identifying potential issues or opportunities. This reflection phase helps agents understand the significance of current observations.

- Plan: Using insights from both current signals and historical records, agents develop response strategies. They can evaluate multiple options based on past results and present conditions.

- Act: Agents either recommend or automatically execute the best course of action. Each action and its results become part of the historical record, improving future decisions.

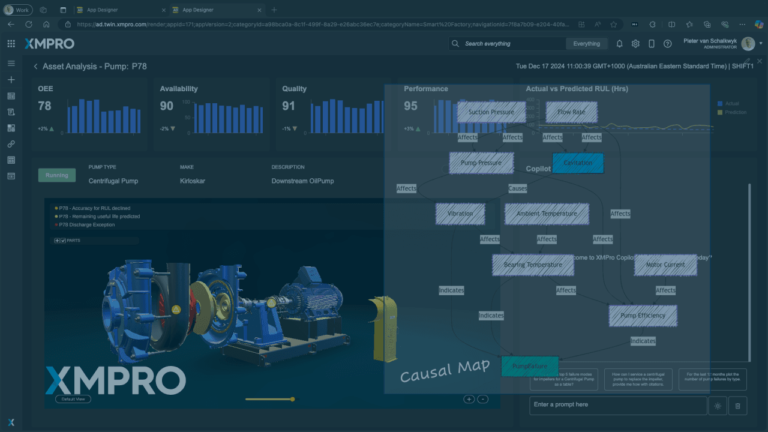

This cognitive approach means our agents don’t just follow predefined workflows – they actively learn and adapt. For example, when monitoring a critical pump system, an agent:

- Combines vibration signals with maintenance history to understand equipment health

- Correlates current performance with historical patterns to spot potential issues

- Evaluates possible responses based on past maintenance outcomes

- Takes or recommends actions that balance immediate needs with long-term reliability

The memory cycle continues as agents learn from each decision’s results, building a deeper understanding of your operations over time. This creates a system that gets smarter and more effective with each operational cycle.

The Technical Challenge

Building AI agents that can handle both records and signals requires solving several technical challenges:

- Connecting to diverse data sources across industrial operations

- Processing real-time streams while managing historical data

- Ensuring data quality and synchronization

- Enabling agents to learn from both types of information

- Supporting collaboration between multiple agents

How XMPro Data Streams Bridges the Gap

XMPro addresses these technical challenges through our Data Streams capability. Data streams serve as the core foundation that enables agents to work and scale effectively with both records and signals.

Here’s how XMPro Data Streams handles each technical challenge:

- Data Source Integration: Data Streams connects to over 200 different industrial data sources using native protocols. This means agents can access everything from industrial control systems and IoT sensors to enterprise databases and cloud services without custom coding.

- Stream Processing: The system processes real-time data streams while maintaining connections to historical databases. Data Streams handles time-series data, event streams, and state changes, ensuring agents have access to both current conditions and historical context.

- Data Quality Management: Data Streams includes built-in data validation, filtering, and synchronization capabilities. The system handles missing data, corrects timing issues, and ensures agents work with reliable information.

- Advanced Analytics and AI Integration: Data Streams embeds multiple types of analytics and AI directly in the data processing flow. This includes traditional statistical analysis, machine vision systems, and causal analytics. Agents can use these capabilities both for processing incoming data and as tools for specific tasks, enabling sophisticated multi-step analysis and decision-making.

- Learning Support: Our stream processing engine maintains both short-term and long-term data storage. This lets agents access recent operational data for immediate decisions while building long-term learning from historical patterns.

- Agent Collaboration: Data Streams creates a shared operational data layer that all agents can access. This enables agents to share information, coordinate responses, and learn from each other’s experiences. It also enforces the “Rules of Engagement” for multi-agent generative systems.

The technology works like a nervous system for industrial operations. It collects signals from across the facility, processes them in real-time, and makes both current and historical information available to agents for decision-making.

For example, when monitoring a production line, XMPro Data Streams:

- Collects real-time sensor data about equipment performance

- Synchronizes this with quality measurements and production records

- Validates and processes all information in real-time

- Makes both current and historical data available to agents

- Enables multiple agents to coordinate their responses

This foundation ensures that agents can effectively combine signals and records to make better operational decisions.

Real Business Impact

Organizations using this comprehensive approach see measurable improvements:

- Reduced unplanned downtime through better prediction and prevention

- Improved product quality through tighter process control

- Lower operating costs through optimized resource use

- Enhanced safety through faster issue detection and response

Looking Forward

The future of industrial software isn’t just about replacing application layers on databases with agents. It’s about creating truly cognitive systems that understand and act on the full spectrum of industrial data. This requires agents that can:

- Process both historical records and real-time signals

- Learn continuously from operational experience

- Collaborate to solve complex problems

- Adapt to changing conditions

- Make decisions that combine past learning with present awareness

- Enable new agentic capabilities such as continuous causal awareness through causal analysis

The transition to these intelligent industrial agents will happen faster than most organizations expect. While full adoption won’t happen overnight, the pace of change in AI capabilities means organizations need to start building their foundations now. Those who wait too long will find themselves struggling to catch up as early adopters gain compounding advantages from their agents’ accumulated learning and optimization.

Organizations that successfully combine records and signals early will build sustainable advantages in efficiency, reliability, and competitiveness. Each day of operation gives their agents more data to learn from and optimize against. Like compound interest, these early investments in the right capabilities will generate increasing returns over time.

This isn’t just about adopting new technology – it’s about developing the organizational capabilities needed to thrive in an agent-driven industrial future. The time to start is now, while organizations can still make this transition deliberately and strategically rather than reactively.

As we move forward, the distinction between records and signals will become increasingly important. Industrial AI agents must handle both types of data effectively to deliver real value. This goes beyond Nadella’s vision of replacing application layers – it’s about creating truly intelligent industrial operations that can learn from the past while responding to the present.

Our GitHub Repo has more technical information if you are interested. You can also contact myself or Gavin Green for more information.

Read more on MAGS at The Digital Engineer

About the Author: Pieter van Schalkwyk is the CEO of XMPro, which focuses on helping organizations bridge the gap between industrial operations and enterprise systems through practical AI solutions. With over thirty years of experience in industrial automation and digital transformation, Pieter leads XMPro’s mission to make industrial operations more intelligent, efficient, and responsive to business needs.

This article originally appeared in XMPro CEO’s Linkedin newsletter here