COMPOSITE DIGITAL TWIN

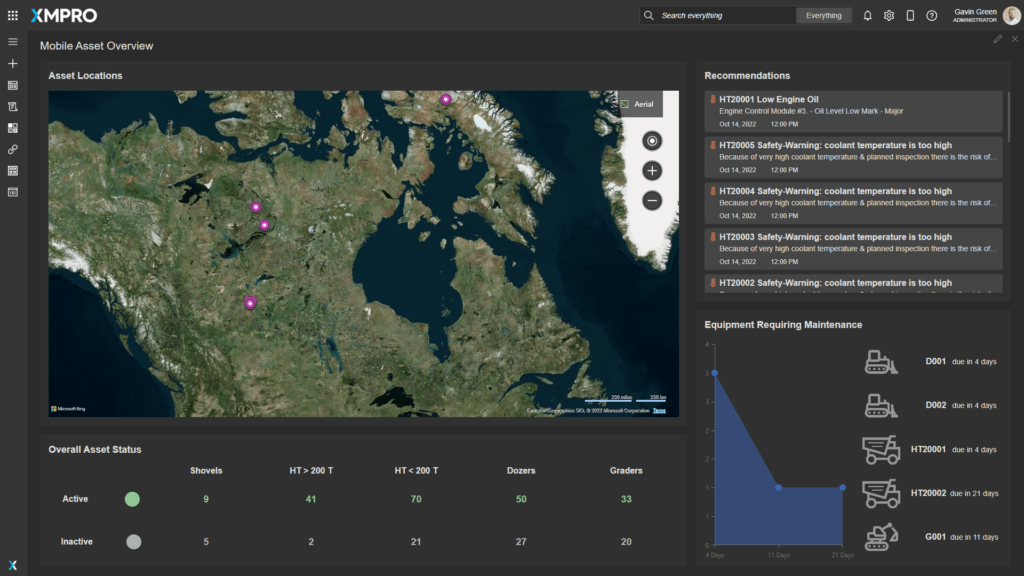

Mobile Asset Health

- Monitor when mobile assets will require maintenance to optimize your team’s work schedule

- Visually display asset location on a map to get real-time visibility into how your assets are moving

- Leverage pre-built rules for detecting and acting on high temperatures from your equipment sensors

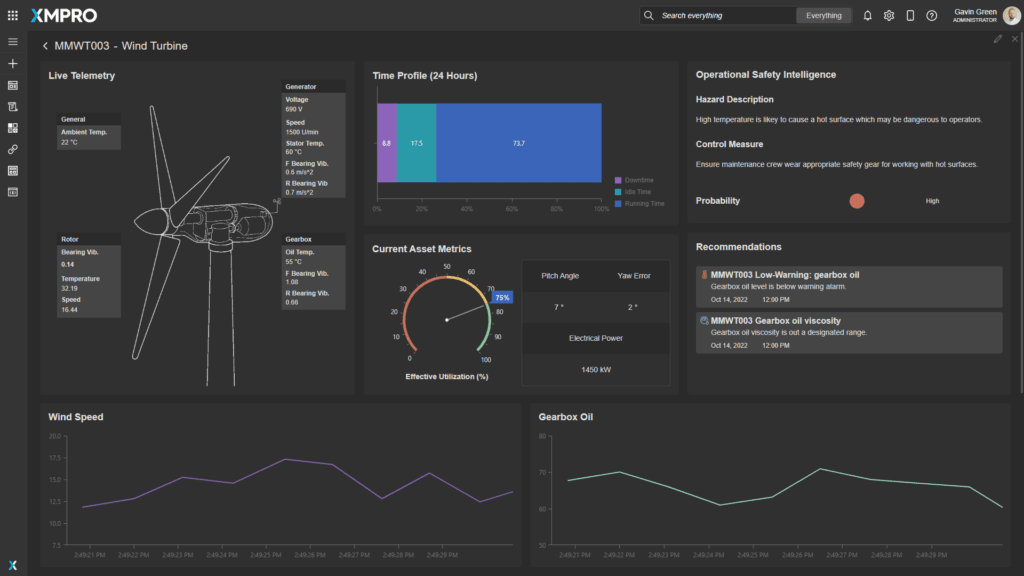

DISCRETE DIGITAL TWIN

Wind Turbine

- Create a virtual representation of your wind turbine using pre-built DTDL models based on the IEC 61400-25 standard

- Overlay real-time telemetry data onto a schematic for a holistic view of the wind turbine’s health

- Visualize trends for key metrics like gearbox oil levels and wind speed

Use XMPro Blueprints for Quick Time To Value

Easily import Blueprints, Accelerators and Patterns into your environment, providing a starting point for configuring your own solutions.

Featured Blueprints

Blast Furnaces & Autoclaves

The expert engineers at Hatch have used XMPro to create an application for casting guidance using our 3D visualization and simulation capabilities. Customers can enter their operating parameters to receive tailored guidance on tap hole placement.

Operational Safety

TUV SUD have translated their safety rules into recommendation rules in XMPro that can be triggered based on real-time data. These rules provide the description, control measure and probability for safety hazards.

Centrifugal Pumps & HPGRs

WEIR have built apps that enable their customers to monitor the real-time health of their assets across multiple sites. These reusable apps monitor parameters like temperature, vibration and have advanced charting capability built-in using D3.

XMPro Blueprint Library

Value Chain Health

Monitor each part of the daily value chain to identify bottlenecks and keep on track of periodic production targets.

Root Cause Analysis

Analyze and capture the failure mechanisms for a variety of asset types using a 5-Why Analysis.

Control Room Health

Provide control room advisors with real-time visibility into the operating health of multiple operational areas and sites.

Fans

Combine real-time health signals like discharge pressure, flow rate and motor current with recent work order history.

Crushers

Manage crusher health with recommendations for feed rate, nitrogen pressure and OEE score.

Conveyors

Maximize production by identifying excessive differentials in amperage and temperature.

Tailings Management

Coming soon

Carbon Reporting

Coming soon

Supply Chain Control Tower

Coming soon