Introduction

In today’s fast-paced and ever-evolving manufacturing industry, companies are constantly looking for ways to improve efficiency, productivity, and quality. One innovative solution that has been gaining traction in recent years is the use of a digital twin. But what exactly is a digital twin, and how can it benefit smart manufacturing?

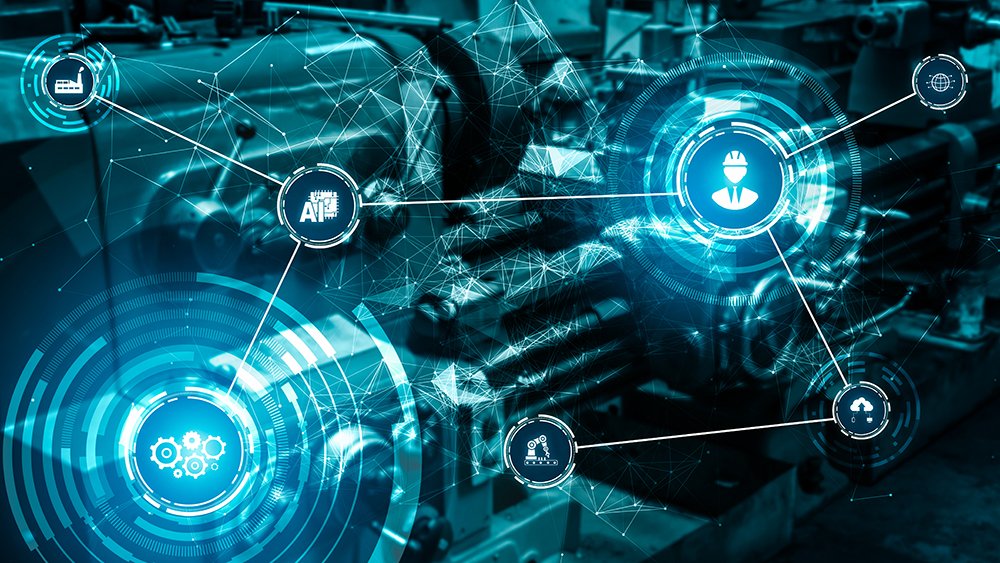

A digital twin is a virtual replica of a physical product, process, or system. It can be used to simulate and analyze various aspects of the manufacturing process, including design, testing, and performance. By creating a digital twin, companies can gain valuable insights into how their products and processes will perform in the real world, without the need for costly and time-consuming physical experimentation.

The use of a digital twin in smart manufacturing can bring numerous benefits, such as improved design and testing, increased efficiency and productivity, improved communication and collaboration, and many more.

In this blog post, we will explore these benefits in more detail, and how they can help companies stay ahead of the competition in today’s manufacturing landscape.

Benefit 1 : Improved design and testing

One of the most significant benefits of using a digital twin in smart manufacturing is the ability to improve the design and testing of products and processes. With a digital twin, companies can simulate and analyze various aspects of the manufacturing process before it is physically implemented. This allows for virtual experimentation and testing, which can save time and money in the long run.

For example, a company that manufactures cars can create a digital twin of their assembly line. By simulating the assembly process, the company can identify potential bottlenecks and inefficiencies before they occur in the real world. This can help them optimize the assembly process, reducing downtime and increasing productivity.

Additionally, a digital twin can be used to simulate and optimize the manufacturing process. Companies can use a digital twin to analyze data from various sensors, such as temperature and pressure, to identify areas where improvements can be made. This can help companies increase efficiency, reduce waste, and improve the overall quality of their products.

In short, the use of a digital twin in smart manufacturing can help companies improve the design and testing of their products and processes, resulting in a more efficient and cost-effective manufacturing process.

Benefit 2 : Increased Efficiency and Productivity

One of the primary benefits of using a digital twin in smart manufacturing is the ability to increase efficiency and productivity. With a digital twin, companies can monitor and analyze performance in real-time, identify and solve problems quickly, and reduce downtime and maintenance costs.

For example, a digital twin can be used to monitor and analyze data from various sensors, such as temperature and pressure, to identify potential issues with equipment before they become critical. This can help companies plan for maintenance and repairs, reducing downtime and increasing productivity.

Furthermore, a digital twin can be used to identify and solve problems quickly. By analyzing data in real-time, companies can identify issues and take corrective action before they become critical. This can help companies reduce downtime, increase efficiency, and improve the overall quality of their products.

Additionally, the use of a digital twin in smart manufacturing can also result in cost savings. By reducing downtime and maintenance costs, companies can save money and increase competitiveness in the manufacturing industry.

In summary, the use of a digital twin in smart manufacturing can help companies increase efficiency, productivity and reduce costs, which can lead to a more competitive and profitable manufacturing process.

Benefit 3 : Improved Communication and Collaboration

Communication and collaboration is essential for any manufacturing environment. With a digital twin, companies can share and access data across different departments and teams, making it easier to make informed decisions based on accurate and up-to-date information.

For example, a digital twin can be used to share information between the design and manufacturing departments. By sharing data, the design department can ensure that the product is designed to meet the requirements of the manufacturing process, reducing the risk of errors and delays.

Additionally, a digital twin can be used to improve collaboration among different teams. By providing real-time data and analysis, teams can work together more effectively to identify and solve problems, improve efficiency, and increase productivity.

Furthermore, the use of a digital twin in smart manufacturing can also improve customer service. Companies can use a digital twin to provide real-time updates on production progress and delivery schedules, respond quickly to customer requests and concerns, and improve overall customer satisfaction.

In conclusion, the use of a digital twin in smart manufacturing can help companies improve communication and collaboration among different departments and teams, resulting in a more efficient and responsive manufacturing process.

Benefit 4 : Predictive Maintenance

Another key benefit of using a digital twin in smart manufacturing is the ability to perform predictive maintenance. Predictive maintenance is a technique that uses data and analysis to predict when equipment will need maintenance and plan accordingly. This can help companies reduce downtime and increase productivity.

For example, a digital twin can be used to monitor the performance of equipment in real-time. By analyzing data from various sensors, such as temperature and vibration, a digital twin can identify potential issues with equipment before they become critical. This can help companies plan for maintenance and repairs, reducing downtime and increasing productivity.

Additionally, the use of a digital twin in smart manufacturing can also help companies identify potential safety hazards. By simulating and analyzing the manufacturing process, companies can identify potential hazards and take corrective action before they occur in the real world. This can help companies improve safety and reduce the risk of accidents.

Overall, the use of a digital twin in smart manufacturing can help companies perform predictive maintenance, reduce downtime, improve safety, and increase productivity.

In summary, the use of a digital twin in smart manufacturing can help companies perform predictive maintenance, which can lead to a more efficient and cost-effective manufacturing process.

Benefit 5 : Improved Quality Control

Another significant benefit of using a digital twin in smart manufacturing is the ability to improve quality control. With a digital twin, companies can monitor and analyze production data in real-time, identify and address quality issues quickly, and track and trace products throughout the production process.

For example, a digital twin can be used to monitor and analyze data from various sensors, such as temperature and pressure, to identify potential issues with equipment before they become critical. This can help companies address quality issues quickly and reduce the risk of defects or nonconformities.

Additionally, a digital twin can be used to track and trace products throughout the production process. By monitoring and analyzing data in real-time, companies can ensure that products are manufactured to the correct specifications, reducing the risk of errors and defects.

Furthermore, the use of a digital twin in smart manufacturing can also lead to cost savings. By reducing the risk of defects and nonconformities, companies can save money and increase competitiveness in the manufacturing industry.

In summary, the use of a digital twin in smart manufacturing can help companies improve quality control, reduce defects and nonconformities, and increase competitiveness in the manufacturing industry.

Benefit 6 : Enhanced Flexibility and Scalability

Another benefit of using a digital twin in smart manufacturing is the ability to enhance flexibility and scalability. With a digital twin, companies can adapt to changing market conditions and customer demands, and scale production up or down as needed.

For example, a digital twin can be used to simulate and analyze the manufacturing process, allowing companies to identify areas where improvements can be made. By making these improvements, companies can increase efficiency and reduce waste, which can help them adapt to changing market conditions and customer demands.

Additionally, a digital twin can be used to scale production up or down as needed. By monitoring and analyzing data in real-time, companies can identify areas where production needs to be increased or decreased. This can help companies respond quickly to changes in demand, which can lead to increased efficiency and reduced costs.

Furthermore, the use of a digital twin in smart manufacturing can also lead to cost savings. By increasing efficiency and reducing waste, companies can save money and increase competitiveness in the manufacturing industry.

In summary, the use of a digital twin in smart manufacturing can help companies enhance flexibility and scalability, increase efficiency, reduce costs, and increase competitiveness in the manufacturing industry.

Benefit 7: Improved Safety

Another important benefit of using a digital twin in smart manufacturing is the ability to improve safety. With a digital twin, companies can simulate and identify potential safety hazards, and monitor and enforce safety protocols in real-time.

For example, a digital twin can be used to simulate the manufacturing process, allowing companies to identify potential hazards, such as heavy machinery or hazardous materials. By identifying these hazards, companies can take corrective action before they occur in the real world, improving safety and reducing the risk of accidents.

Additionally, a digital twin can be used to monitor and enforce safety protocols in real-time. By analyzing data from various sensors, such as temperature and pressure, companies can ensure that safety protocols are being followed, which can help them improve safety and reduce the risk of accidents.

Furthermore, the use of a digital twin in smart manufacturing can also lead to cost savings. By improving safety, companies can reduce the risk of accidents, which can lead to lower insurance costs and reduced downtime.

In conclusion, the use of a digital twin in smart manufacturing can help companies improve safety, reduce the risk of accidents, and lead to cost savings.

Benefit 8: Improved Data Management

Another benefit of using a digital twin in smart manufacturing is the ability to improve data management. With a digital twin, companies can collect, store, and analyze data from various sources, making it easier to make informed decisions based on accurate and up-to-date information.

For example, a digital twin can be used to collect data from various sensors, such as temperature and pressure, and store it in a central database. This can help companies analyze data in real-time, identify issues and take corrective action, and improve overall efficiency and productivity.

Additionally, a digital twin can be used to analyze data from various sources, such as customer feedback and market research. By analyzing this data, companies can make informed decisions about product development, marketing, and other areas of the business.

Furthermore, the use of a digital twin in smart manufacturing can also improve data security. By collecting and storing data in a central database, companies can protect it from unauthorized access and ensure compliance with data privacy regulations.

In summary, the use of a digital twin in smart manufacturing can help companies improve data management, make informed decisions, and improve data security.

Conclusion

In conclusion, the use of a digital twin in smart manufacturing can bring numerous benefits to companies, including improved design and testing, increased efficiency and productivity, improved communication and collaboration, predictive maintenance, improved quality control, enhanced flexibility and scalability, improved safety and improved data management. By using a digital twin, companies can gain valuable insights into how their products and processes will perform in the real world, without the need for costly and time-consuming physical experimentation. This can lead to cost savings, increased competitiveness, and improved overall efficiency in the manufacturing industry. Companies that are looking to stay ahead of the competition should consider implementing a digital twin in their manufacturing process.

In addition to the benefits outlined above, smart manufacturers should consider using XMPro’s No Code Digital Twin Composition Platform as a way to easily and quickly create and manage digital twins. The platform allows for the creation of digital twins without the need for coding or programming knowledge, making it accessible to a wide range of users. It also allows for real-time monitoring and analysis of data, as well as the ability to connect with various sensors, systems and third-party applications. Using XMPro’s platform, manufacturers can streamline their digital twin creation process, and easily manage and update their digital twins as needed. This can lead to faster implementation of digital twin technology and improved efficiency in the manufacturing process.