Download the exclusive guide by submitting the form:

Preview

This guide will help you understand exactly what a digital twin is and how you can use it to manage your operations in real-time.

After reading this guide, you’ll know about:

- The different types of digital twins

- How to use AI & machine learning with digital twins

- Blockchain & digital twins

- How to design digital twin applications

Let’s get started.

About The Author

I’m Pieter van Schalkwyk, the CEO of XMPro.

I’m an experienced engineer and technologist focused on helping asset-intensive companies improve situational awareness, process efficiency and decision making with the XMPro Operations Intelligence platform.

I started my career as a plant engineer and accrued ten years of engineering experience before making the switch to IT. I’ve since led the development of business performance management solutions for more than twenty years. I hold a Bachelor’s in Mechanical Engineering and a Master’s in Information Technology.

I’m currently the Digital Twin Consortium Natural Resources Work Group chair. And I served as co-chair of the Industrial Internet Consortium (IIC) Digital Twin Interoperability Task Group chair for four years. In February 2019, I received the IIC Technical Innovation Award.

My passion is helping industrial companies solve the challenges of operating in a world of real-time data.

I’ve distilled my years of research, discussions with industry leaders and experience working with industrial customers into this guide. My goal is to give you a clear roadmap of how to create digital twin applications that deliver real value to your organization.

Contents

Download the PDF of this 3000-word guide

Since this is a long guide, you might want to grab a PDF and read it on the go:

This way, you can print it out, take notes, mark the key sections, or save it on your computer for future reference.

Chapter 1

What Is a Digital Twin?

The XMPro Digital Twin Definition

A digital twin is an instance of a digital model that represents an entity, which includes assets, processes, and systems which are sufficient to meet the requirements of a set of use cases.

I’ll expand on this definition to explain each of those concepts.

Digital Model

A digital twin model typically describes the characteristics, attributes, and behavior of an entity type.

If you take a Warman AH slurry pump as an example of an entity type, you will create a digital model for that type of pump. It would consist of various data types like time-series data, analytical models, and 3D models (we cover all six data types later in this guide). You can have a hundred different pumps of the same kind that all use a standardized model.

Instance

A crucial part of our definition of a digital twin is that it is an instance of a digital model.

You might have a hundred Warman AH slurry pumps that use the same model. However, each pump’s instance of that model creates a unique digital twin.

The digital twin for each pump uses the same model as others of the same type, but each pump has a unique instantiation with unique information.

Watch the video below for a simple explanation of this concept.

Data in a digital twin usually doesn’t come from a single source. It’s important to understand that a digital twin is not a single massive data lake that contains all the information about an entity.

It’s about the way the model describes where the information lives. The model is not the digital twin. The model is a description of characteristics, attributes, and behaviors that define what a digital twin’s structure looks like, but the twin is the unique instance for a specific entity.

Entity

The Oxford Dictionary defines an entity as, “a thing with a distinct and independent existence.”

Our digital twin definition explicitly says that an entity includes assets, processes, and systems. You can build digital twins of more than just your physical assets. I’ll explain more about this in the section on the types of digital twins.

What we mean by “sufficient to meet the requirements of a set of use cases,” is that the idea is not to create an uber digital twin that can do everything for everybody.

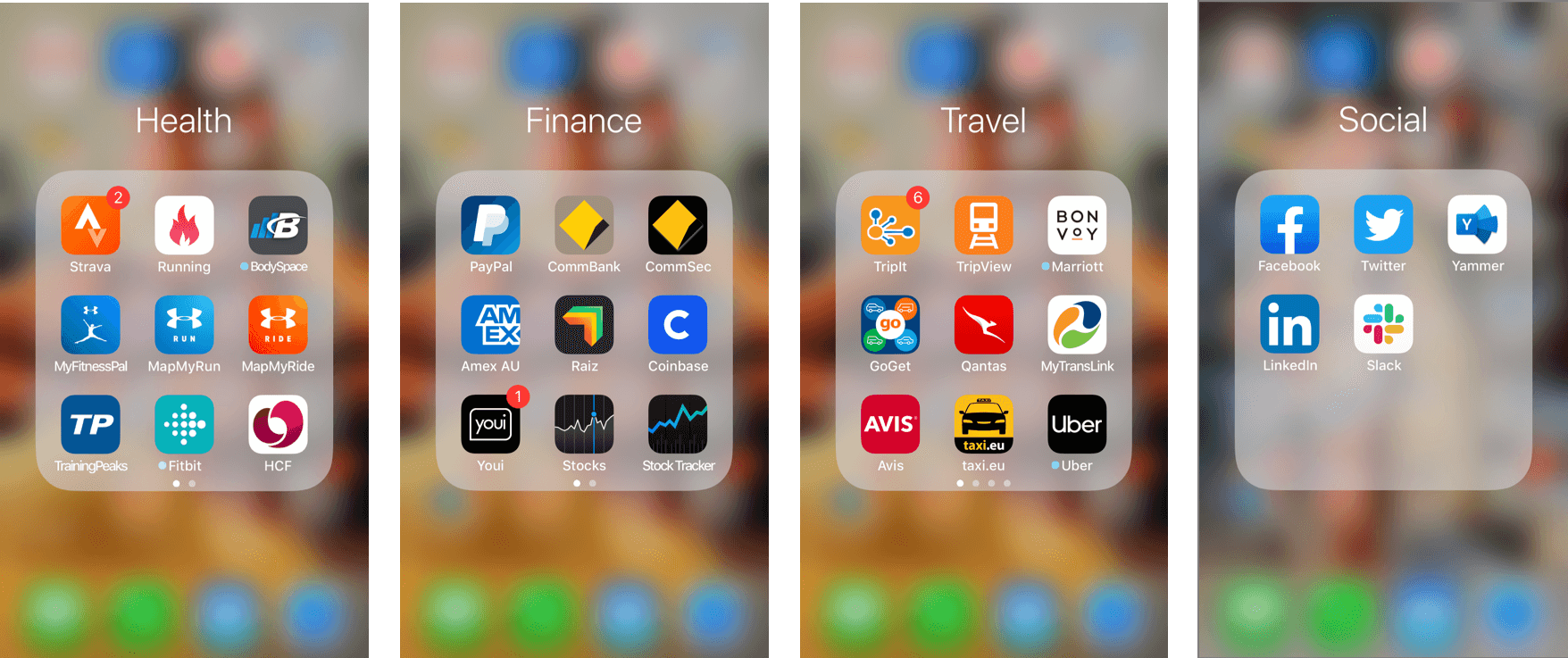

Your banking app is the digital twin of your financial health. It’s not the same as the twin that describes your travel plans or your training regime for a triathlon.

Industrial Digital Twin Categories

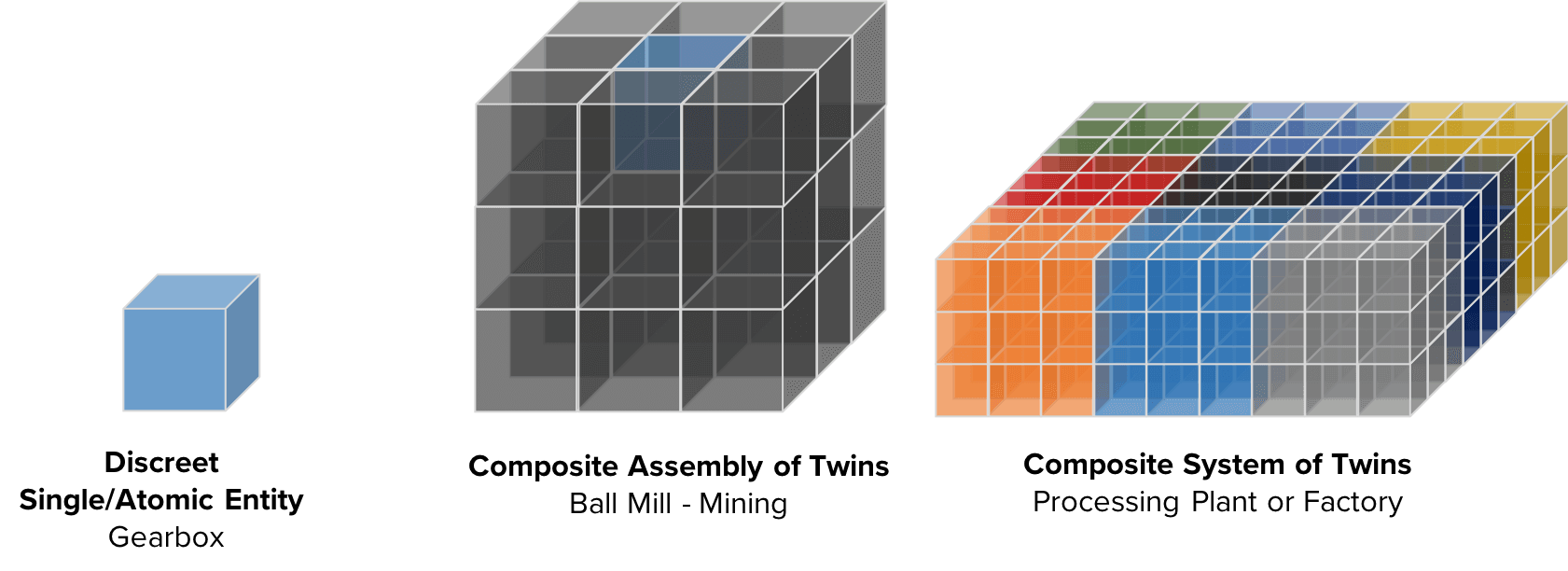

XMPro’s Industrial Digital Twins is modelled based on 2 primary patterns:

- Discrete or atomic Digital Twins

- Composite Digital Twins

- Composite Assembly Twin

- Composite System Twin

Discrete Digital Twin

A discrete Digital Twin is the lowest level of abstraction that is still sufficient to meet the requirements of a specific use case. It is often a single or atomic entity where it adds no value to break it down in components or parts, e.g. the gearbox or motor for a Ball Mill in mining. It doesn’t need to be broken down into the sub-parts as the status and monitoring is reported at this entity level.

Composite Digital Twin

A composite Digital Twin is a combination of discrete Digital Twins that represent an entity comprised of multiple individual components or parts. A composite Digital Twin can be an Assembly Twin like a Ball Mill in Mining or a System Twin that comprises multiple Assembly Twins such as the Processing and Refinement Plants.

It can be depicted as a cube with the sides representing data from the six data types I explain in chapter 6.

Chapter 2

The 5 Benefits of Digital Twin Technology

1. Share Data Across Silos

One of the main benefits of using a digital twin is that you can share data across the different silos that exist in your organization.

Different areas of the business have traditionally captured and stored data in their own repositories. However, a digital twin can use a proxy to collect data from sensors and other sources instead of each silo capturing its own data. The digital twin model understands the relationship between all the siloed data sources.

2. Manage Operations in Real-Time

A digital twin creates situational awareness by building a holistic picture of the entity it represents. It does more than storing and providing insights based on historical data. It enables real-time operations by providing real-time visibility, getting recommendations, and creating actions based on events in the data.

3. Conduct Simulations & Experiments

It also provides a mechanism to do simulations, where you can experiment on the twin rather than on the real entity. Simulations are particularly useful when applying physical and engineering models like finite element methods, where you want to bring in data from multiple sources.

When you have real-time data, you can apply predictive analytics to your digital twin. Then you can determine when an asset is likely to fail or how to optimize your operations. You can also make changes to the physical entity based on the insight you gained from applying the analytics to the twin.

4. Improve Trustworthiness

Digital twins help improve the trustworthiness of your systems by giving you a global view of security, reliability, and availability. This improved visibility can help you identify any blind spots in your system.

5. Enable Collaboration

Many organizations now require cross-functional teams. They expect traditional operational technology roles like engineering and maintenance, as well as IT, automation engineers, and data scientists, to work together to improve operations. Having a digital twin can enable collaboration across your teams by providing a shared understanding of what an entity looks like when it is represented in a digital format.

Chapter 3

Types of Digital Twins

Digital twins are use case driven as per the definition above. XMPro identified three patterns for IoT use cases and created three digital twin types based on these patterns:

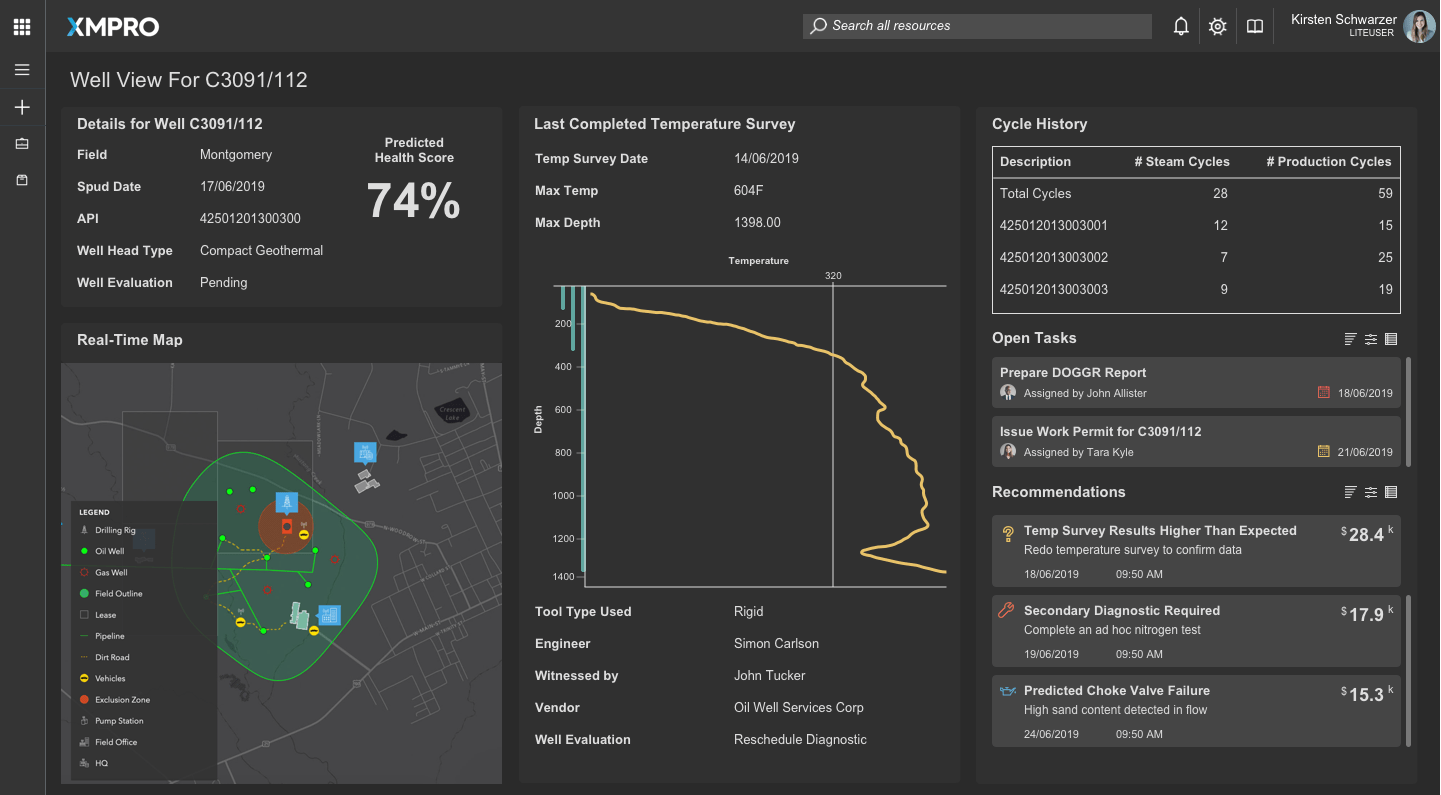

Status Twin

Typically used for basic condition monitoring applications such as dashboards and simple alerting systems. It indicates operating parameters and is generally created with visualization tools. XMPro provides dashboard and HMI views in support of these twins.

Operational Twin

Provides more extensive information that is typically used in decision support by operators, reliability engineers, and other decision-makers. It is linked to a set of actions or workflows where users can interact with the twin and change operating parameters where control capability is allowed.

Simulation Twin

Leverages different types of simulation or artificial intelligence capabilities to predict, forecast, or provide insight into future operational states. You can use it for predictive maintenance or to improve the recovery yield of a processing plant.

Chapter 4

How to Use AI & Machine Learning in Digital Twins

Embedding AI and machine learning in the DNA of your digital twins can help your organization be more competitive at real-time operations.

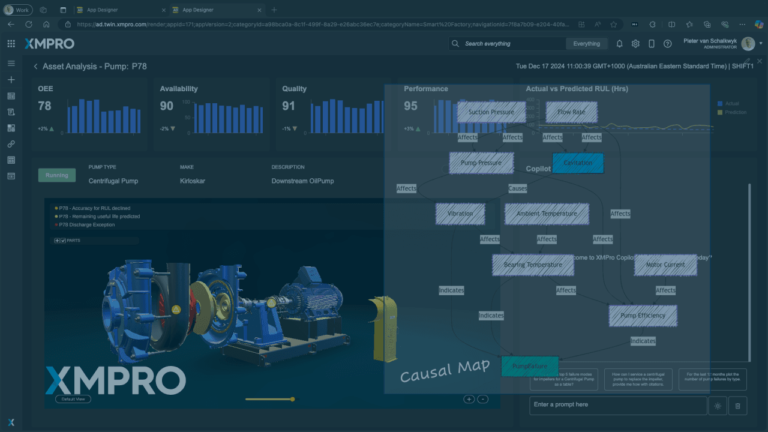

Real-Time Analytics

As a digital twin ingests data in real-time, it can apply AI and machine learning to look for anomalous behavior, predict future states, and optimize production. This advanced real-time analytics is the first step to getting the most value out of your digital twin.

Decision Support

This additional layer of intelligence can be used to display predictions from your digital twin. It provides decision support for your engineers when they need to make real-time decisions. By providing details and predictions about metrics like remaining useful life or stock levels, you can empower your team to respond faster to critical business events.

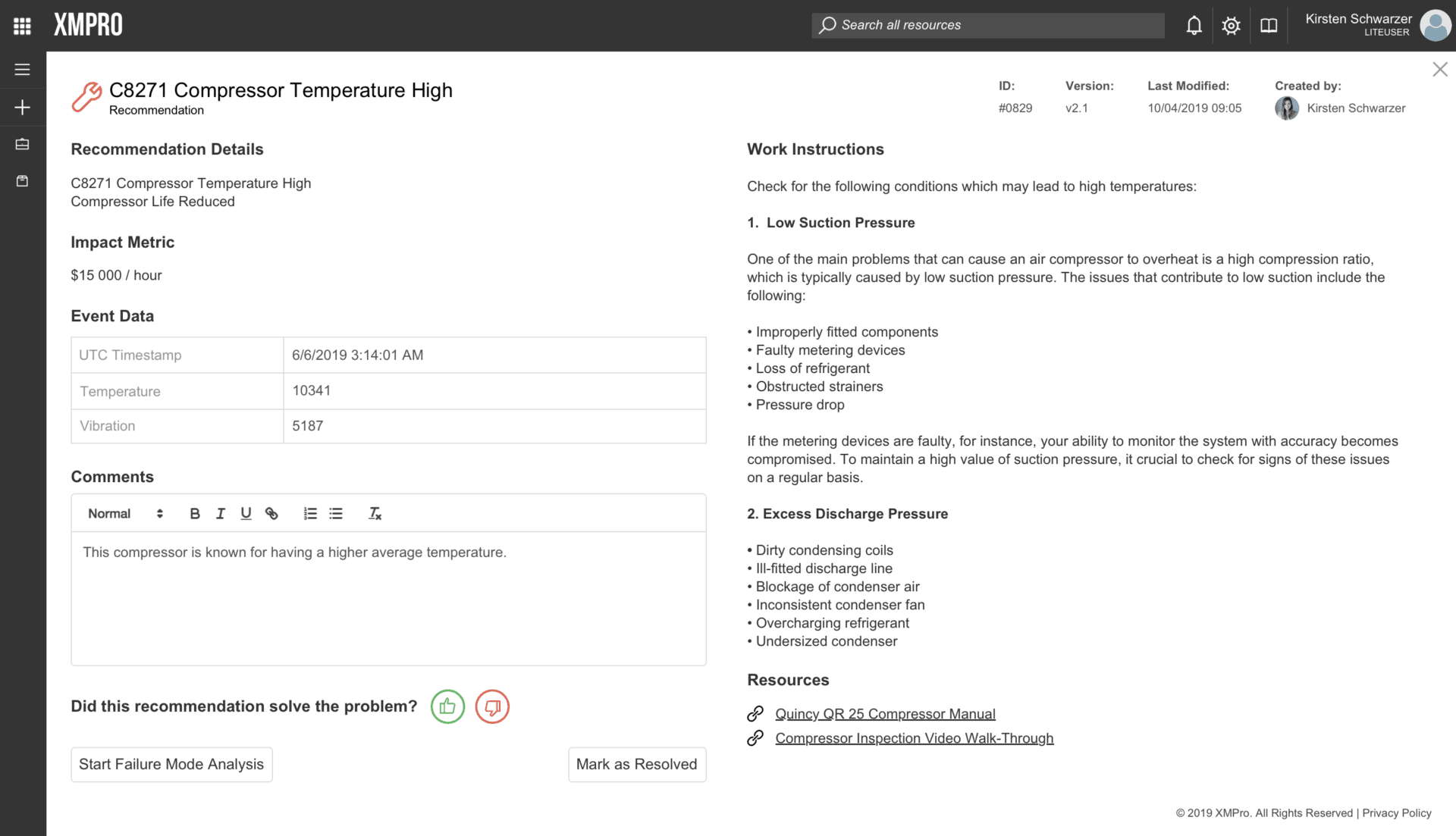

Prescriptive Analytics & Recommendations

The final way to leverage AI and machine learning in your digital twins is to use them for prescriptive analytics and to create recommendations on the best action to take next based on their predictions. In this scenario, your digital twin will do more than provide you with real-time status updates. It will help you and your team take the actions that are most likely to produce the best result based on real-time data.

You might use a digital twin to predict stock levels at different nodes of your supply chain or predict the remaining useful life of a machine. AI and machine learning provide the essential capabilities to help you maximize the value you get from your digital twins.

Chapter 5

How To Combine Blockchain & Digital Twins

Blockchain was named one of Gartner’s Top 10 Strategic Technology Trends for 2019. As we move into 2020, more use cases for this technology are emerging in industrial environments.

When it comes to digital twins, the primary use case for distributed ledger and blockchain technology is around storing information from the digital twin and how it interacts on the blockchain.

The second use case is to let digital twins engage in smart contracts with other digital twins or systems.

Storing Digital Twin Information

Here are the key benefits of storing digital twin data in a distributed ledger:

- Information is not managed centrally by a central organization.

- Records are immutable and require validation, which reduces the risk of tampering.

- Information can be transferred seamlessly while maintaining the integrity of the data.

When assets change ownership, the corresponding records about that asset all need to move to the new owner. One example is when a mining organization sells one of its processing plants or mines. Using digital twins and distributed ledger technology can help simplify this transfer process.

Another example is keeping statutory records where there are multiple stakeholders involved. In cases like this, government agencies, certification bodies, and the owners/operators of the plant equipment all need to have confidence that no one tampered with the records.

Smart Contracts

A smart contract is essentially a set of code that runs in a distributed ledger when two or more bodies agree on the trigger event.

Smart contracts are an area of emerging opportunity for digital twins in industrial scenarios. As digital twins become the proxy for a physical entity, it can interact with a smart contract in real-time and execute the contract based on certain conditions in the data.

If the digital twin has AI and business-rule capabilities, it can apply analytics to the data to decide when and how to execute the smart contract.

Other use cases for blockchain and digital twins include micropayments and virtual currencies. In those scenarios, a digital twin may have a wallet and pay for services rendered in real-time, but those are further down the track.

We see the storing of critical records and digital twins interacting with smart contracts as areas of immediate opportunity in this space.

Chapter 6

The 6 Types of Digital Twin Data

We’ve grouped the data you can use to create your industrial digital twins into six main categories:

- Physics-based models (FEM, Thermodynamic, Geological)

- Analytical Models (Predictive Maintenance)

- Time series data & historians

- Transactional data (ERP, EAM)

- Master Data (EAM, AF, BPM)

- Visual Models (CAD, AR, VR, BPM, BIM, GIS, and GEO)

You will select data from each of these categories based on the problem you want your twin to solve. By combining data from multiple types and sources, you can create a digital twin that gives you a holistic real-time view of the entity you are monitoring.

Digital Twins & Heterogeneous Data Sources

As mentioned before, there’s no single repository or database that contains all the information for a digital twin. There are too many data types generated by different systems and stored in various formats. Creating a single massive repository would also lead to duplication and potential errors in the digital twin data.

You won’t be creating a new repository. However, it is vital to create a link between the different data sources for the digital twin and to understand their relationships. The relationship between the data from various sources could be linear, in which you can use a point-to-point view to connect them. Alternatively, they could use a graph-based structure to map how the data relates to the entity and what the relationships are in the data.

Data Standardization Initiatives

There are several standardization initiatives currently being developed for digital twins. You don’t want to create a mega database, because there are many different data formats, structures, and standards emerging.

In manufacturing, for example, Industry 4.0’s Asset Administration Shell is looking at how to represent this data from a manufacturing perspective. In aerospace, there are StEP initiatives, and in oil and gas, the OSDU is describing subsurface data in a standardized format.

Chapter 7

Digital Twin vs. Digital Thread

As we mentioned at the start of this guide, a digital twin is a digital representation of an entity. It can include historical information and operating information as well as analytics capabilities and a recommendation engine to enable real-time operations. It provides you with a dashboard view into how the entity is performing right now and what you can anticipate in the future.

The digital thread represents the birth-to-retirement records of the entity as it moves through different stages of its lifecycle. Each time something significant happens in the life of an entity, the digital thread creates a snapshot and adds it to the existing records. Significant events can include things like critical maintenance or anomalous operational behavior.

For example, when you create a digital twin for a manufactured product, you often won’t have visibility into how the customer uses it. In this case, you would build the digital twin around the product design. It can include the CAD model, engineering details, and even sensor data about the quality of the product during testing.

When you look at owner-operators in industries like oil and gas, mining, and process manufacturing, operators can create digital twins that start with the design, construction and commissioning of a plant. Before the plant even starts operating, this lifecycle data can become part of the digital thread.

When you eventually retire an entity, you will not only have a comprehensive digital twin with data from the various data types. You’ll also have complete birth-to-retirement records for the entity in the form of a digital thread.

Chapter 8

How to Create Digital Twin Applications

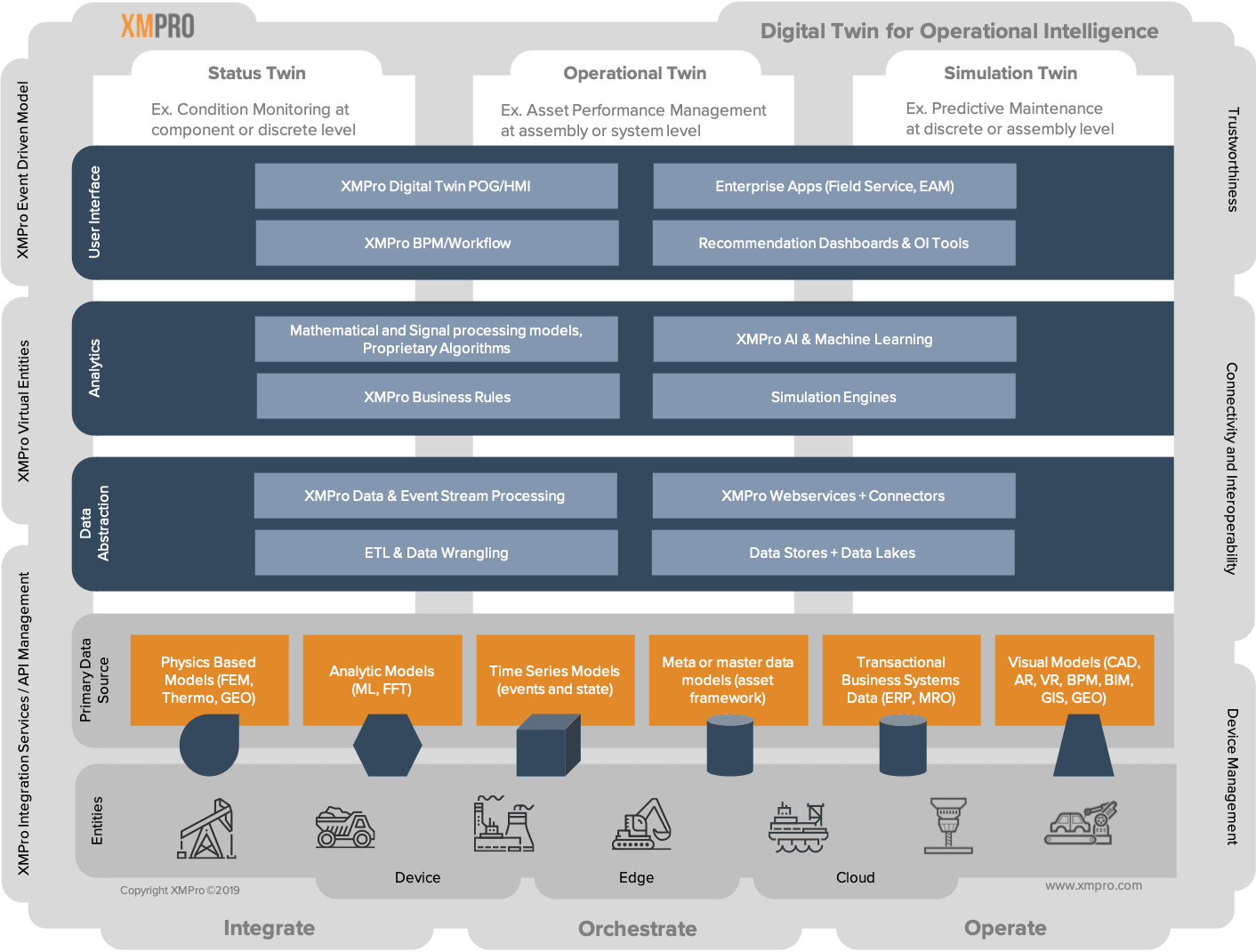

XMPro Digital Twin Reference Architecture

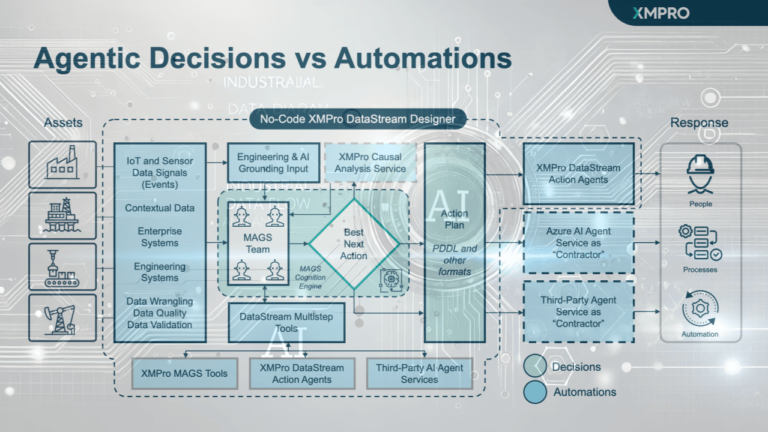

The XMPro Digital Twin Reference Architecture is primarily focused on twins for owner-operators in asset intensive industries such as mining, oil and gas, and energy and utilities. It is also focused on operational and continuous intelligence applications where the twins are continuously updated with real-time information from sensors and other services such as weather, maintenance systems, or oil analysis laboratories.

The reference architecture above shows how you can use XMPro’s Agile Application Studio to design and run Digital Twins using our Integrate, Orchestrate and Operate approach.

The architecture is structured around the “use case” principle, and the example above demonstrates the status, operational and simulation twin scenarios.

The primary data sources are based on the six dimensions explained earlier. Themes such as trustworthiness, integration and connectivity are implicitly part of the architecture.

The three key focus areas of the architecture are:

[bsf-info-box icon_type=”custom” icon_img=”id^9084|url^https://xmpro.com/wp-content/uploads/2019/09/Data-Abstraction-2.png|caption^null|alt^null|title^Data-Abstraction-2|description^null” img_width=”48″ title=”Data Abstraction” heading_tag=”h4″]Collecting, aggregating, wrangling, and storing data from multiple data sources.[/bsf-info-box]

[bsf-info-box icon_type=”custom” icon_img=”id^9083|url^https://xmpro.com/wp-content/uploads/2019/09/Analytics-2.png|caption^null|alt^null|title^Analytics-2|description^null” img_width=”48″ title=”Analytics” heading_tag=”h4″]Business rules, algorithms, machine learning and simulation requirements to create meaning from the data.[/bsf-info-box]

[bsf-info-box icon_type=”custom” icon_img=”id^9082|url^https://xmpro.com/wp-content/uploads/2019/09/User-Interface-2.png|caption^null|alt^null|title^User-Interface-2|description^null” img_width=”48″ title=”User Interface” heading_tag=”h4″]Provides the user interaction capability through dashboards, workflows, HMI screens etc.[/bsf-info-box]

Create a Minimum Viable Digital Twin

We advise that you start by building a minimum viable version of your digital twin to test your assumptions. We’ve adapted this idea from the Lean Startup approach that has gained popularity in recent years.

By building a minimum viable twin, you can start small, test your assumptions, learn from feedback, and improve rapidly.

Here’s how we recommend building your first digital twin:

Step 1: Start with the Job You Want Your Digital Twin to Do

Think about your digital twin like you would about hiring a person. What job would you want them to do? Figure out what data you need to collect, what decisions the twin will need to make, how it would notify you of critical events, and what actions need to be taken to respond to those events.

Do you recall the digital twin definition from the beginning of this guide? We said that it needs to be a digital representation that is sufficient to meet the requirements of a specific set of use cases.

When you think about a set of use cases, you’re asking, “What is the business problem I’m trying to solve?” It’s important to emphasize that a digital twin is not an uber twin that does everything for everybody. The smart way to design a digital twin is to build it around a specific challenge.

Questions to Ask When Planning a Digital Twin:

- Does it need to continuously monitor something and let you know when an event occurs?

- Should it provide decision support or decision automation, where it applies business rules or looks for anomalies?

- Can it apply machine learning or artificial intelligence? Phrased another way, if your digital twin was a real person, would you like them to use their intelligence and interpret the data?

- Should your digital twin make a recommendation on what to do next, or would you want it to take action on your behalf?

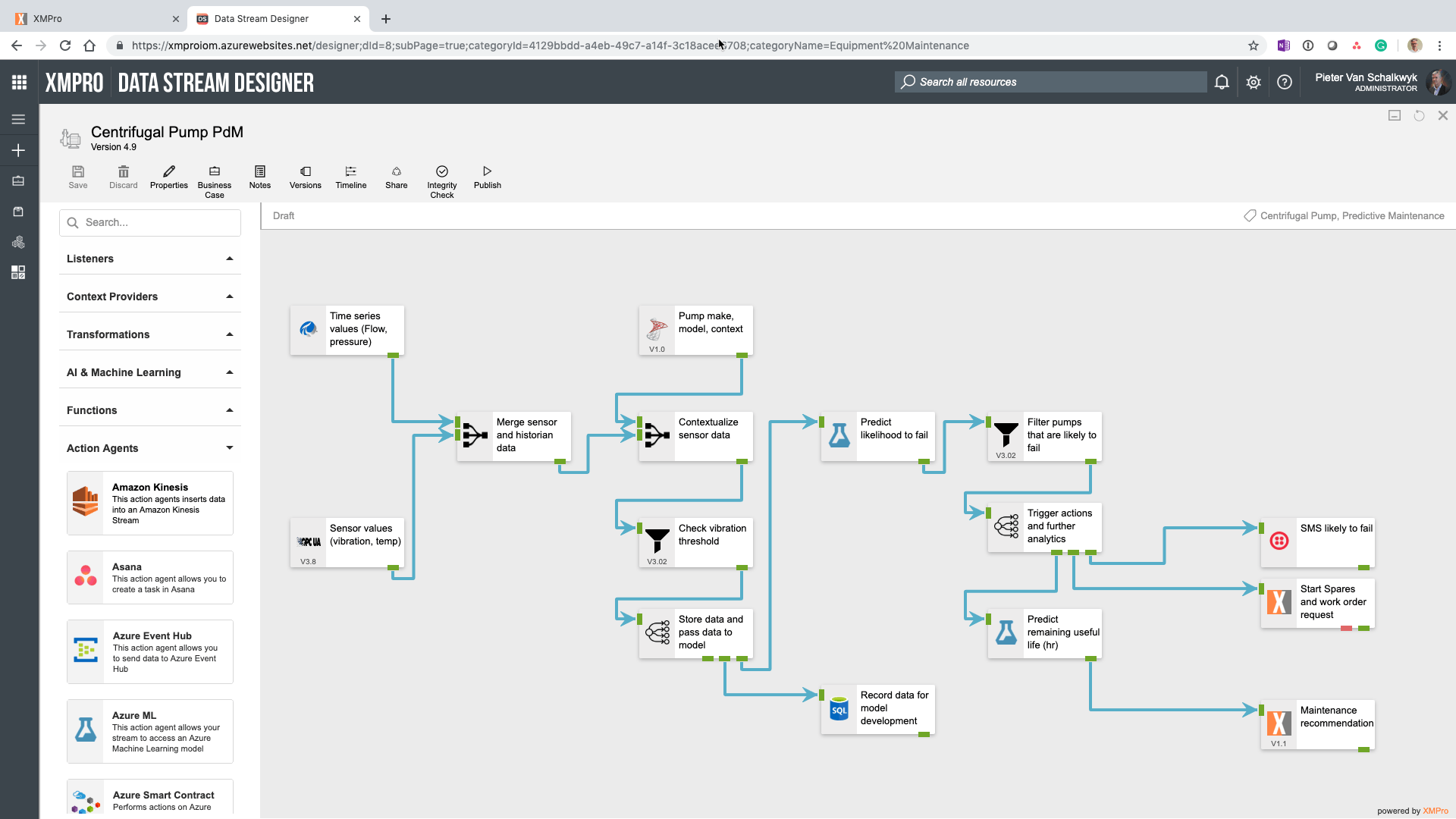

Step 2: Design the Real-Time Data Flow

In the first step, you can use XMPro’s Data Stream designer to visually design the real-time flow of data. You can connect to your different data sources, add in analytics, and trigger recommendations or workflows.

Once you have the data stream set up, you can move on to creating the visual aspect of the twin that will provide situational awareness to your users.

While you can automatically trigger actions with XMPro’s Data Streams, many organizations still prefer showing data to a real person to make the decision. In this case, you can send your data to a real-time XMPro application or a dashboard in a third-party tool.

Step 3: Create the Visualization & Actions

Providing the user with this real-time visualization of the data will help them understand what happened, why it happened, what the trends are, and even what the recommended actions are. With XMPro’s Application Designer, you can build digital twin applications that provide all of this real-time information in a single interface.

Step 4: Iterate & Improve

As you deploy your digital twin application into the real world, you are bound to learn things you never expected. It might be more challenging to get access to the data. You might uncover that your operational problems are more significant than you thought.

You could also learn that this twin could be scaled out to solve this same issue across multiple plants in your organization for even greater ROI.

With XMPro’s Data Stream and App Designer, you can easily tweak your digital twin, ensuring it delivers on the job you hired it to do.

Download the PDF of this 3000-word guide

Since this is a long guide, you might want to grab a PDF and read it on the go:

This way, you can print it out, take notes, mark the key sections, or save it on your computer for future reference.

[ultimate_spacer height=”50″ height_on_tabs=”30″ height_on_tabs_portrait=”30″ height_on_mob_landscape=”20″ height_on_mob=”20″]