Pump Predictive Maintenance: Enhancing Reliability and Efficiency

Introduction

Did you know that unplanned pump failures can cost industries thousands of dollars in lost productivity and emergency repairs? Pumps are critical components in various industrial processes, and their reliability directly impacts operational efficiency. As organizations strive to minimize downtime and optimize performance, predictive maintenance has emerged as a game-changing strategy.

Predictive maintenance offers a proactive solution to ensure pump systems operate reliably and efficiently. By leveraging advanced technologies like IoT sensors, data analytics, and machine learning, organizations can effectively monitor pump health and predict potential issues before they escalate. This approach not only minimizes the likelihood of sudden equipment breakdowns but also significantly reduces maintenance costs and enhances safety across industrial operations.

This article explores the value of pump predictive maintenance, highlighting its benefits, real-world applications, challenges, and future trends, as well as best practices for successful implementation. We will also discuss how XMPro’s Intelligent Business Operations Suite (iBOS) can be an ideal solution for implementing effective predictive maintenance strategies.

The Role of Pumps in Industrial Processes

Pumps play an essential role in a wide range of industrial applications, from chemical processing to water treatment and mining operations. They are used to transfer liquids, control pressure, and facilitate cooling and heating processes. Any disruption in pump functionality can lead to severe consequences, including production delays, equipment damage, and even safety hazards for workers.

Due to their critical role, ensuring pumps are maintained in optimal condition is of paramount importance. Traditional maintenance approaches, such as reactive and preventive maintenance, have inherent limitations. Reactive maintenance often leads to costly downtime, while preventive maintenance relies on fixed schedules that may not accurately reflect the actual condition of the pump.

Predictive maintenance, on the other hand, is a data-driven approach that can address these limitations, providing a more efficient and cost-effective solution for maintaining pump health.

What is Predictive Maintenance?

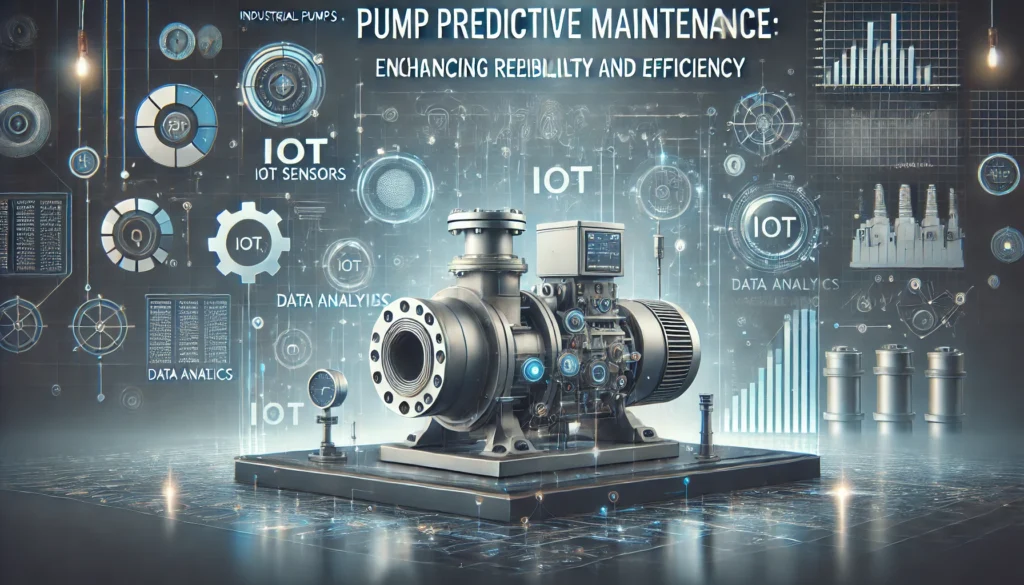

Predictive maintenance is a proactive approach that leverages advanced technologies to anticipate equipment failures before they occur. Unlike reactive maintenance, which focuses on repairing equipment after it breaks down, or preventive maintenance, which involves scheduled servicing based on predefined intervals, predictive maintenance uses real-time data to determine when maintenance is truly needed.

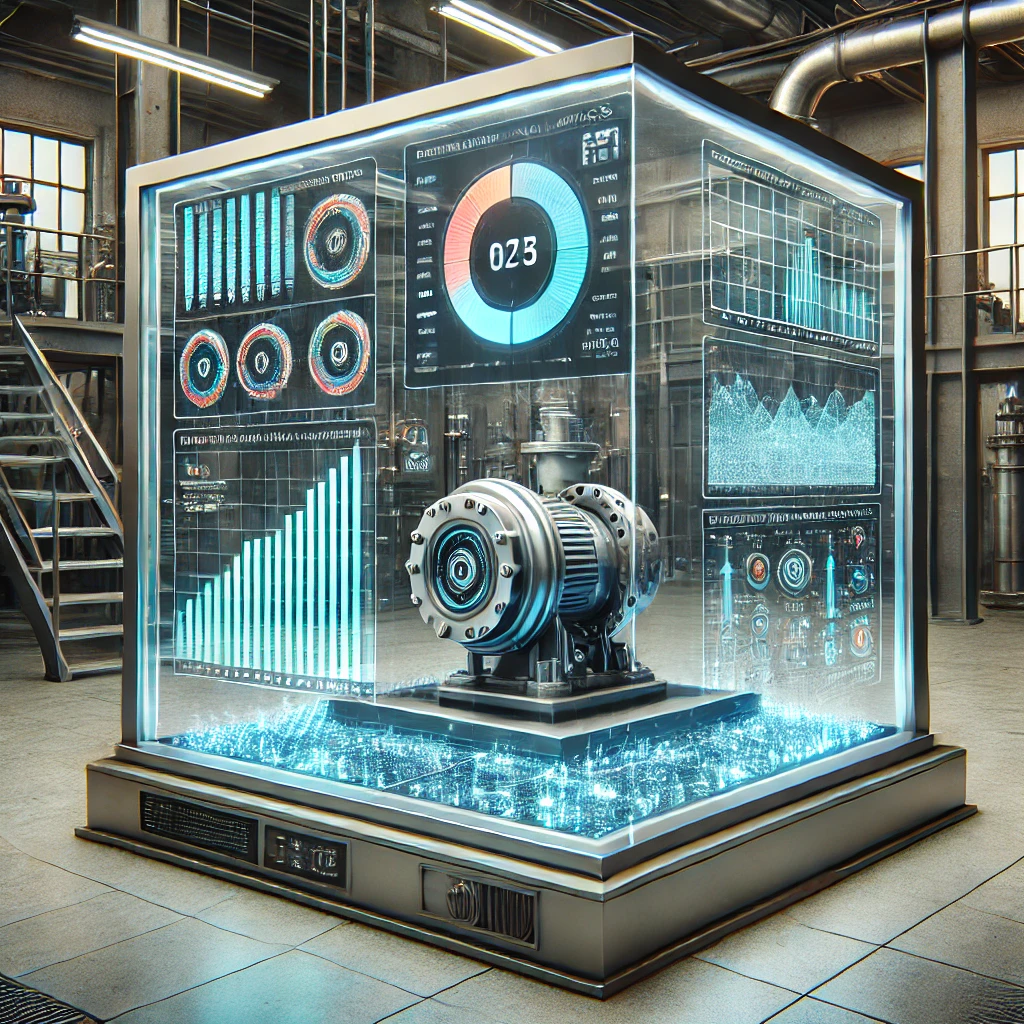

By utilizing tools such as IoT sensors, data analytics, and machine learning, organizations can monitor the health of their pumps in real time. This approach allows for timely interventions, reducing the likelihood of unexpected breakdowns and costly repairs. Predictive maintenance provides the insights needed to schedule maintenance activities based on actual equipment conditions rather than arbitrary timelines, ensuring pumps operate at peak efficiency.

Key Components of Predictive Maintenance

To understand how predictive maintenance works, it’s essential to explore the key components that make this strategy effective:

IoT Sensors

IoT sensors are the foundation of predictive maintenance. These sensors collect data on various parameters, such as vibration, temperature, pressure, and flow rates, providing insights into pump performance. By continuously monitoring these parameters, organizations can identify deviations from normal operating conditions that may indicate potential issues.

Data Analytics

Once data is collected from IoT sensors, it must be analyzed to extract meaningful insights. Advanced data analytics tools process the collected data to identify patterns, trends, and anomalies. These analytics help maintenance teams understand the condition of their pumps and predict when maintenance is required.

Machine Learning

Machine learning algorithms play a crucial role in predictive maintenance by analyzing historical data to improve the accuracy of predictions over time. These algorithms learn from past equipment behavior and use this knowledge to predict future failures.

Benefits of Predictive Maintenance for Pumps

Predictive maintenance offers several key benefits for pump operations, including cost savings, increased reliability, and enhanced safety. Let’s explore these benefits in detail and see how XMPro can enhance these outcomes:

Cost Savings

One of the most significant advantages of pump predictive maintenance is its potential for cost savings. By identifying issues early, organizations can avoid the high costs associated with unplanned downtime and emergency repairs. Predictive maintenance enables scheduled maintenance activities, allowing companies to allocate resources more efficiently.

XMPro’s platform helps reduce costs by automating the detection of issues and optimizing maintenance schedules. By using XMPro, a manufacturing plant can reduce maintenance costs by up to 25%, thanks to real-time monitoring and efficient resource allocation.

Furthermore, predictive maintenance with XMPro helps extend the lifespan of pumps by addressing issues before they cause significant damage. By maintaining pumps in optimal condition, organizations can reduce the need for expensive replacements and spare parts, leading to additional cost savings.

Increased Reliability

Predictive maintenance enhances the reliability of pumps by ensuring they operate within optimal parameters. Continuous monitoring allows for the early detection of anomalies, such as unusual vibrations or temperature fluctuations. Addressing these issues promptly helps maintain pump performance and extends equipment lifespan.

XMPro’s real-time monitoring and alerting capabilities ensure that maintenance teams receive timely notifications of any anomalies. A case study involving a chemical processing facility demonstrated that implementing predictive maintenance using XMPro led to a 40% reduction in pump failures. By continuously monitoring pump conditions and addressing issues before they escalated, the facility significantly improved its operational reliability.

Enhanced Safety

Safety is paramount in industrial operations, and predictive maintenance contributes to a safer working environment by preventing catastrophic failures that could lead to accidents or injuries. Pumps that malfunction can create hazardous conditions, such as leaks, fires, or explosions. By ensuring that pumps are functioning correctly, organizations can protect their workforce and minimize risks.

XMPro provides real-time alerts and automated workflows that ensure maintenance teams can respond quickly to potential safety hazards. For instance, a water treatment plant that adopted XMPro for predictive maintenance reported a decrease in safety incidents related to pump failures. By proactively addressing potential issues, the facility not only improved safety but also enhanced employee morale and confidence in the workplace.

Why XMPro is Ideal for Predictive Maintenance

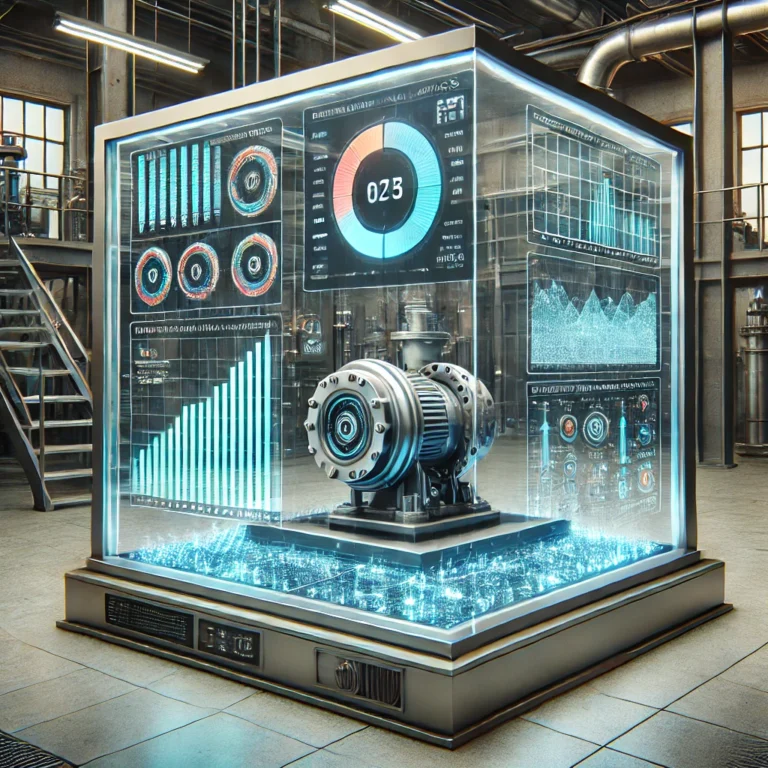

XMPro’s Intelligent Business Operations Suite (iBOS) is an ideal solution for implementing predictive maintenance for pumps due to its comprehensive features and capabilities:

- Advanced Analytics and Machine Learning: XMPro leverages advanced analytics and machine learning models to analyze historical and real-time data, providing accurate predictions of pump failures and maintenance needs. The platform’s ability to learn from historical data helps improve the accuracy of predictions over time.

- Real-Time Alerts and Automated Workflows: XMPro’s real-time monitoring and alerting system ensures that maintenance teams are promptly notified of any anomalies. The platform also provides automated workflows, enabling quick and efficient responses to potential issues.

- Integration Capabilities: XMPro integrates seamlessly with existing IoT sensors, SCADA systems, and other data sources, providing a unified view of pump performance. This integration capability ensures a smooth transition to predictive maintenance without disrupting ongoing operations.

- User-Friendly Interface: XMPro’s user-friendly interface makes it easy for maintenance teams to access and interpret data, empowering them to take proactive action. The platform’s intuitive design ensures that maintenance teams can easily navigate and use its features effectively.

- Proven Success in Real-World Applications: XMPro has been successfully implemented by various companies across industries, yielding significant improvements in operational efficiency, cost savings, and safety. These success stories demonstrate XMPro’s effectiveness in enhancing predictive maintenance strategies.

By using XMPro, organizations can achieve significant improvements in operational efficiency, reduce downtime, and enhance safety. The platform’s comprehensive features make it an ideal choice for implementing and optimizing predictive maintenance strategies for pumps.

Challenges and Considerations

Common Obstacles

While the benefits of predictive maintenance are clear, organizations may face challenges when adopting this strategy. Initial costs for implementing new technologies and integrating them with existing systems can be significant. Additionally, there may be resistance to change within the organization.

XMPro helps address these challenges by providing a scalable and flexible platform that integrates with existing systems, minimizing disruption. The platform’s user-friendly interface also helps reduce resistance to change by making it easy for teams to adopt new predictive maintenance practices.

Best Practices

To overcome these challenges, organizations should consider the following best practices:

- Start Small: Begin with a pilot program to test predictive maintenance on a few critical pumps before scaling up. XMPro’s platform is scalable, allowing organizations to start small and expand their predictive maintenance initiatives over time.

- Invest in Training: Provide training for maintenance teams to ensure they understand how to use new technologies effectively. XMPro offers training resources and support to help teams make the most of the platform.

- Foster Collaboration: Encourage collaboration between maintenance, operations, and IT teams to facilitate a smooth transition. XMPro’s integrated platform makes it easy for cross-functional teams to share insights and best practices, leading to more effective predictive maintenance strategies.

- Monitor and Adjust: Continuously monitor the performance of predictive maintenance initiatives and make adjustments as needed. XMPro provides tools for tracking performance metrics and making data-driven decisions to refine maintenance strategies.

Future Trends in Pump Predictive Maintenance

Emerging Technologies

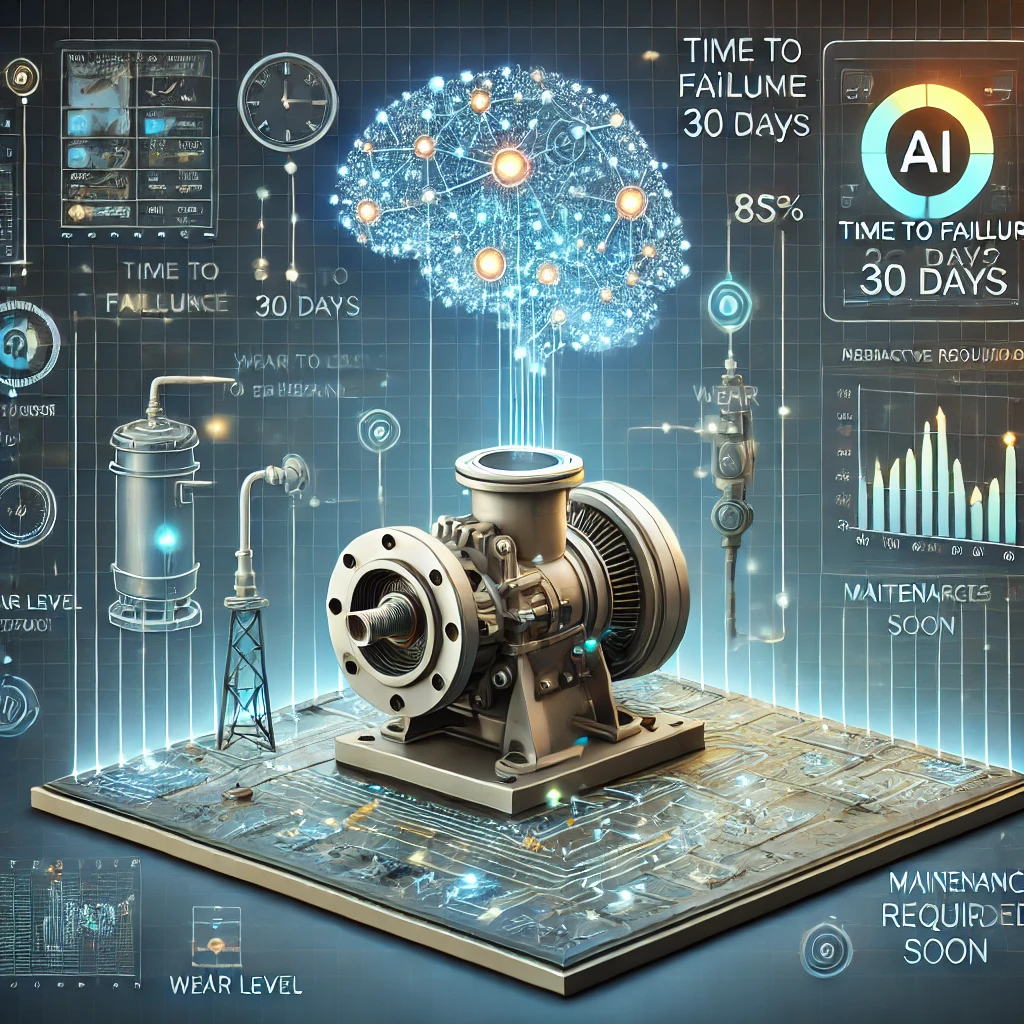

The future of predictive maintenance is bright, with emerging technologies poised to enhance its effectiveness. For instance, advancements in artificial intelligence (AI) will enable even more accurate predictions of pump failures. AI algorithms can analyze vast amounts of data and identify complex patterns that may not be apparent through traditional analysis methods.

XMPro is at the forefront of these technological advancements, integrating AI and machine learning to provide organizations with cutting-edge predictive maintenance capabilities. The platform’s ability to create digital twins—virtual replicas of physical assets—allows for sophisticated simulations and analyses, optimizing maintenance activities and improving equipment performance.

Industry Outlook

As industries continue to embrace digital transformation, predictive maintenance will play a crucial role in shaping the future of pump operations. Organizations that adopt these strategies, particularly with the support of platforms like XMPro, will likely see improved efficiency, reduced costs, and enhanced safety. The ability to predict and prevent equipment failures will become a competitive advantage, allowing companies to maintain uninterrupted operations and deliver consistent quality to their customers.

Furthermore, as more companies recognize the value of predictive maintenance, the demand for skilled professionals in this field will increase. XMPro’s user-friendly platform helps bridge the gap by providing maintenance teams with the tools and knowledge they need to implement effective predictive maintenance strategies.

Conclusion

In summary, pump predictive maintenance offers significant benefits for industrial operations, including cost savings, increased reliability, and enhanced safety. By leveraging advanced technologies like IoT sensors, data analytics, and machine learning, organizations can proactively manage their pump maintenance strategies, ensuring operational excellence in an increasingly competitive landscape.

XMPro’s Intelligent Business Operations Suite is an ideal solution for implementing predictive maintenance for pumps. With advanced analytics, machine learning, real-time alerts, and seamless integration capabilities, XMPro empowers organizations to optimize their maintenance strategies and achieve better outcomes. Predictive maintenance not only reduces the risk of unplanned downtime but also helps extend the lifespan of critical equipment, leading to long-term cost savings and improved operational efficiency.

As the industry evolves, embracing predictive maintenance with the right tools, such as XMPro, will be essential for staying competitive and ensuring that operations run smoothly and safely.

Additional Resources

Engagement Opportunities

We invite you to share your experiences with pump maintenance and predictive strategies in the comments below. How has predictive maintenance impacted your operations? Let’s foster a discussion and learn from each other’s insights. If you found this article valuable, consider sharing it within your network to spread the knowledge and inspire others to embrace predictive maintenance.