Pieter Van Schalkwyk

CEO at XMPRO

Industrial manufacturing companies invest $1.1 trillion annually in digital transformation, yet 64% remain in early implementation stages [1]. This striking contrast reveals a fundamental truth about digital evolution in industrial settings. Companies don’t need to feel ashamed of their current position, but they do need a clear-eyed strategy to move forward. The gap between investment and maturity creates both challenges and opportunities for organizations willing to take a pragmatic approach.

The Reality of Digital Transformation Maturity

Digital transformation requires more than buying new technology. It demands fundamental changes to processes, culture, and business models all at once. Most companies find themselves in the early stages of this journey, setting up basic data collection and connecting operational systems. This foundational work lacks the glamour of advanced AI but creates the necessary conditions for future progress.

Value realization in these early stages often progresses slowly. Initial use cases typically focus on efficiency improvements rather than fundamentally changing operations or business models. Companies might achieve 10-15% maintenance cost reductions or 5-7% energy savings, but transformative outcomes require time and sustained effort. This reality creates pressure from stakeholders expecting faster returns on digital investments.

Companies that accurately assess their current position gain a substantial advantage. They can develop realistic strategies that match their maturity level and deliver genuine value. Those who misjudge their position often waste resources implementing technologies they can’t effectively use.

The path to digital maturity follows a natural progression that companies can’t skip without consequences. Each stage builds essential capabilities needed for the next level of advancement.

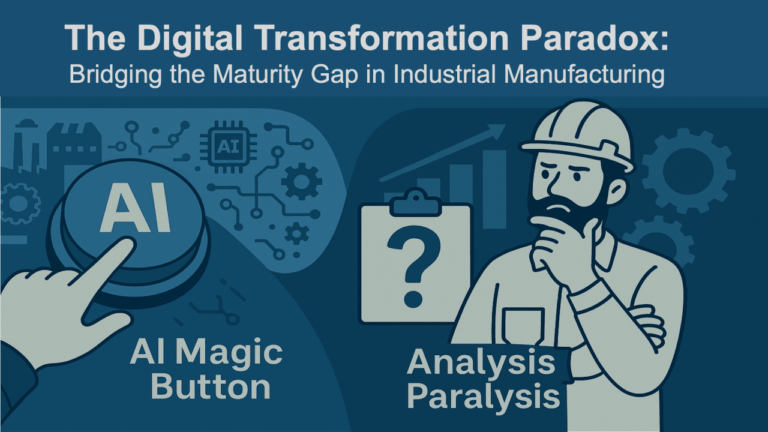

Avoiding Common Transformation Pitfalls

Two dangerous extremes derail digital transformation efforts. The first is “Magic Button Syndrome“ – believing AI can solve complex problems without proper foundations. Companies suffering from this mindset implement sophisticated AI in environments lacking the necessary infrastructure. This creates expensive disappointments that undermine confidence in digital initiatives.

The second trap is Analysis Paralysis – endlessly studying and planning while delaying actual implementation.Organizations caught here invest heavily in assessments but fail to generate tangible benefits or organizational learning. Both extremes prevent meaningful progress toward digital maturity.

Remember that AI remains just a tool, not an end in itself. Effective transformation starts with identifying specific business problems worth solving. The technology should serve clear use cases that deliver measurable business value. Companies that deploy AI for AI’s sake often create impressive demos but fail to impact operational performance where it matters.

Successful organizations take a balanced approach. They build necessary foundations while implementing appropriate advanced capabilities that deliver measurable value. This balanced progression builds momentum and develops the technical infrastructure needed for sophisticated applications.

The Competitive Stakes Are High

The competitive implications of digital transformation are substantial and growing. Michael Carroll recently warned at the 2025 ARC Leadership Forum: “If you are not embracing AI and Agentic Way of Work with a Causal Analysis basis, your assets will have someone else’s name on them in 5 years.” (paraphrased from my notes). This stark assessment captures the urgency of the transformation imperative.

Digital transformation creates competitive advantage through multiple mechanisms:

- Efficiency gains – reducing maintenance costs by up to 30% and improving asset utilization by 15-20%

- Enhanced decision-making capabilities that respond effectively to market shifts and supply disruptions

- New business models and service offerings that can reshape industry competitive dynamics

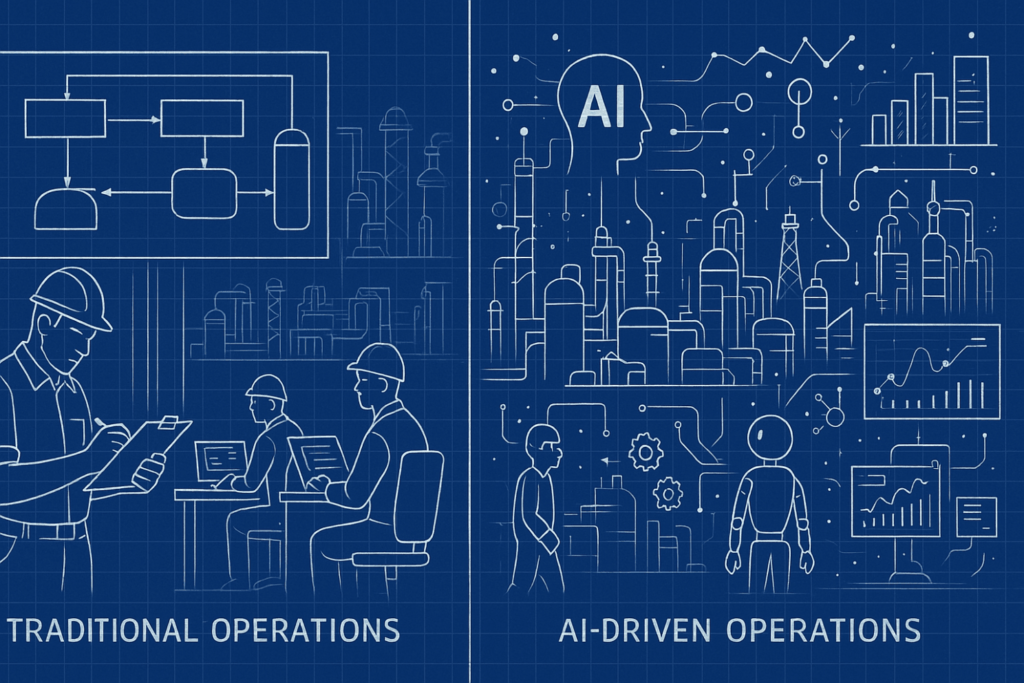

Beyond these well-recognized benefits lies a powerful but often overlooked dimension: Operation Model Change. While Business Model Change focuses on new revenue streams through products and services, Operation Model Change transforms how work gets done. This shift creates massive value through operational effectiveness, not just efficiency. Companies that rethink their operational models can achieve step-change improvements in key performance indicators, far beyond incremental efficiency gains.

Operation Model Change: Created by ChatGPT 4o

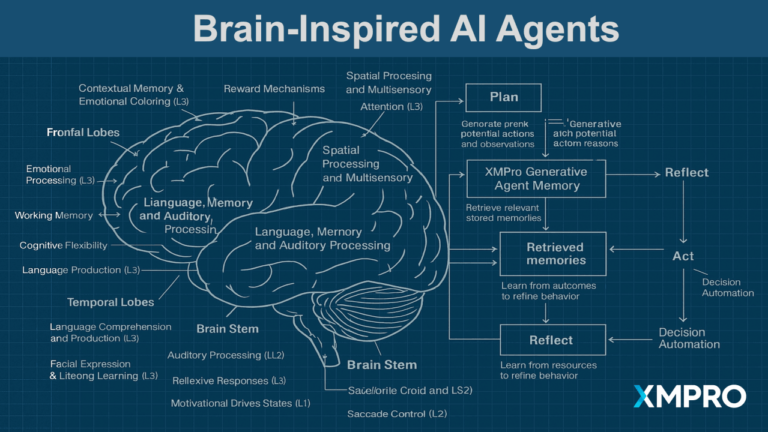

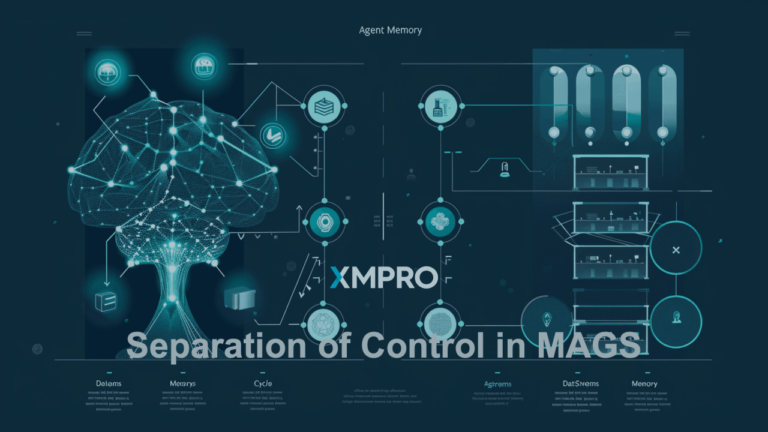

Operation Model Change might include moving from scheduled to condition-based maintenance, shifting from reactive to predictive operations, transforming from centralized to distributed decision-making, or employing Multi Agent Generative Systems (MAGS) as virtual workers. The level of Operation Model Change will be determined by your current level of transformation. Where you start is not important; it is the fact that you are moving to the next level that unlocks the transformational opportunities. These fundamental shifts in work patterns create sustainable advantages that competitors struggle to replicate.

Digital transformation isn’t optional for industrial companies that want to remain relevant. The question isn’t whether to transform but how to do it effectively given your current capabilities.

A Blueprint for Practical Progress

Companies need to start with an honest assessment of their current digital maturity. This self-awareness prevents implementing technologies that don’t match organizational readiness. From there, focus on advancing three interconnected dimensions:

- Technical foundations include data infrastructure, integration capabilities, and technology platforms. These elements create the necessary conditions for more advanced applications. Companies often underestimate the importance of this invisible but essential work.

- Operational integration connects new capabilities with daily workflows and processes. This ensures digital tools deliver practical value rather than existing as isolated technological showcases. The most valuable implementations solve specific operational problems.

- Organizational readiness encompasses skills development, leadership alignment, and cultural adaptation. These human factors determine whether technical capabilities translate into business results. The most sophisticated technology fails without the right organizational context.

Progress must occur across all three dimensions in relative balance. Advancement in one area without corresponding growth in others creates friction that slows transformation.

With these foundations in place, always prioritize use cases that solve real business problems. AI implementation should start with a clear problem statement and target concrete business outcomes like reducing downtime, improving yield, or increasing asset utilization. Let business value drive technology adoption rather than implementing AI solutions looking for problems to solve.

Meeting Organizations Where They Are

Being in the early stages of digital maturity isn’t a failure – it’s the reality for most industrial organizations. Different starting points, industry contexts, and organizational characteristics create unique transformation journeys. A steel mill with decades-old equipment faces different challenges than a recently built chemical plant.

Companies succeed when they build capability through incremental wins rather than attempting dramatic leaps. This approach demonstrates value at each stage and creates momentum for continued investment. Start with focused proof-of-value projects that balance feasibility with impact.

The most advanced organizations eventually progress from efficiency improvements to Operation Model Change, where they fundamentally reimagine how work gets done. These transformative changes typically occur after organizations have built solid digital foundations.

Digital transformation proceeds at the pace of organizational learning, not technological possibility. The most successful transformations acknowledge this reality and create conditions for accelerated learning.

Balancing Urgency with Smart Implementation

Companies face a tension between competitive urgency and the methodical nature of effective transformation. Navigating this tension requires what I call “strategic impatience“.

Strategic Impatience – combining relentless forward momentum with clear recognition of current capabilities and constraints.

This approach rejects both magical thinking about technology and excessive caution that prevents progress. It focuses on high-value use cases that show quick returns while building toward larger capabilities. It establishes clear metrics tied to business outcomes rather than technological implementation.

The most successful organizations maintain urgency about their transformation journey while making decisions based on their current capabilities. They avoid comparing themselves to idealized case studies that lack practical context.

A Practical Path Forward

Start instead by identifying opportunities that match your current maturity level with genuine business needs. Focus initially on use cases with clear ROI potential rather than technological sophistication. Manufacturing companies typically find strong returns in predictive maintenance, where even basic implementations can reduce downtime by 15-20%.

Develop a staged implementation plan that delivers value at each phase while building toward more sophisticated capabilities. This creates a self-funding transformation that builds organizational confidence through demonstrated success.

Invest in developing internal capabilities alongside technology implementation. The organizations that succeed long-term build their own expertise rather than remaining dependent on vendors and consultants.

Escape The Paradox

The gap between digital investment and maturity reflects the complex reality of transformation in industrial settings. It shows the time and organizational evolution needed to transform operations at scale.

Companies that recognize their current position and develop stage-appropriate strategies gain substantial advantages. Those that attempt to skip stages or advance unevenly face costly setbacks and missed opportunities.

The urgency of transformation is real, as Mike’s warning makes clear. Yet the most effective response isn’t blind acceleration but strategic coherence – moving forward purposefully with a clear understanding of your current capabilities.

Digital transformation requires both honest self-assessment and relentless forward momentum. Companies that balance these elements position themselves to thrive in an increasingly digital industrial landscape. The journey starts with accepting your current reality while refusing to remain there.

Let me know if you are interested in “stepping into the journey”; no starting point needed.

Source:

[1] PwC – Digital factory transformation in a time of crisis

Pieter van Schalkwyk is the CEO of XMPro, specializing in industrial AI agent orchestration and governance. Drawing on 30+ years of experience in industrial automation, he helps organizations implement practical AI solutions that deliver measurable business outcomes while ensuring responsible AI deployment at scale.

About XMPro: We help industrial companies automate complex operational decisions. Our cognitive agents learn from your experts and keep improving, ensuring consistent operations even as your workforce changes.

Our GitHub Repo has more technical information if you are interested. You can also contact myself or Gavin Green for more information.

Read more on MAGS at The Digital Engineer