Intelligent Multi-Location Windfarm Management

Introduction

In the renewable energy sector, managing multiple windfarms across various locations presents unique challenges. Efficiently monitoring and optimizing the performance of these windfarms is crucial for maximizing energy production and minimizing operational costs. XMPro’s Intelligent Business Operations Suite (iBOS) offers an integrated solution for multi-location windfarm management, leveraging advanced analytics, real-time data monitoring, and predictive maintenance strategies.

The Challenge

Managing multiple windfarms involves several complexities:

- Diverse Geographical Conditions: Each windfarm operates under different weather and environmental conditions, affecting turbine performance.

- Operational Efficiency: Ensuring optimal performance of turbines across all locations to maximize energy output.

- Maintenance Coordination: Scheduling and executing maintenance activities efficiently across various sites.

- Data Integration and Analysis: Collecting and analyzing data from multiple sources to make informed decisions.

The Solution: XMPro iBOS For Intelligent Multi-Location Windfarm Management.

XMPro’s Intelligent Business Operations Suite (iBOS) is adeptly designed to tackle these complexities head-on. It offers a comprehensive and integrated approach, tailored specifically for the nuanced needs of multi-location windfarm management. This approach not only streamlines operations but also enhances overall performance and sustainability. Here’s a closer look at how XMPro iBOS transforms windfarm management through its innovative features and capabilities:

Key Features

Centralized Monitoring and Control:

XMPro iDTS provides a centralized platform for monitoring all windfarms, offering real-time data on turbine performance, weather conditions, and energy output.

Benefit: Enables operators to oversee and manage all sites from a single dashboard, enhancing decision-making and response times.

Predictive Analytics for Performance Optimization:

The suite utilizes predictive analytics to forecast weather patterns and turbine performance, allowing for proactive adjustments to maximize energy production.

Benefit: Increases energy output efficiency and reduces the risk of turbine damage due to adverse weather conditions.

Digital Twin Modeling for Each Windfarm:

Digital twins of each windfarm create virtual models that simulate real-world conditions, enabling scenario analysis and optimization strategies.

Benefit: Facilitates testing and implementation of operational strategies without disrupting actual operations.

Automated Maintenance Scheduling:

Predictive maintenance algorithms schedule maintenance activities based on turbine condition and performance data, coordinating tasks across multiple locations.

Benefit: Reduces downtime and operational costs by optimizing maintenance schedules and resource allocation.

Integration with Renewable Energy Systems:

XMPro iDTS integrates with other renewable energy management systems, providing a holistic view of the energy production ecosystem.

Benefit: Enhances overall energy management and supports grid stability.

Customizable Reporting and Analytics:

The platform offers customizable reporting tools and analytics for performance tracking, regulatory compliance, and financial analysis.

Benefit: Provides insights for strategic planning and continuous improvement.

How XMPro iBOS Modules Work Together To Create This Condition Monitoring Solution

Discover This Solution In Our Product Tour

XMPro Data Stream Designer

XMPRO’s Data Stream Designer lets you visually design the data flow and orchestration for your real-time applications. Our drag & drop connectors make it easy to bring in real-time data from a variety of sources, add contextual data from systems like EAM, apply native and third-party analytics and initiate actions based on events in your data.

Figure 1. Wind Turbine Condition Monitoring Data Stream

This renewable condition monitoring data stream for a wind turbine begins by reading all records from various data sources, including an OPC UA server. The data is then joined and contextualized with sensor data to provide a comprehensive view. Calculated metrics, such as oil levels, are derived from the sensor data. The processed data is broadcasted to multiple endpoints for further analysis. A failure recommendation rule is applied to identify potential issues, and the data is rounded and filtered specifically for wind turbines. The final processed data is then made available for viewing and further action through a visualization platform, ensuring continuous monitoring and proactive maintenance of the wind turbine.

Figure 2. Wind Energy Asset Data Stream

This wind energy asset monitoring data stream collects and processes telemetry data from various sources, including rotor and gearbox, power, yaw, pitch, operational telemetry, and weather and wind services. The data is contextualized with metadata and operational signals, then broadcasted for different calculations. Calculations include yaw error and efficiency, asset health and utilization scores, and predicting the likelihood of failure. Anomalies in operating time series data are identified, and asset reliability and operations data are combined. The system checks spares on location, runs recommendation rules, and stores time series data in an InfluxDB historian. Recommendations and control data are displayed on the XMPro app, and set points are sent to the control unit, ensuring comprehensive monitoring and proactive maintenance of wind energy assets.

Figure 3: Wind Turbine Unity Model For Condition Monitoring

This pump predictive maintenance data stream ingests pressure, flow, temperature, vibration, and sensor health data from multiple sources before it is normalized and combined with contextual data from SAP and Azure Digital Twin. The integrated data is then used to calculate performance metrics, run predictive models, and update Azure Digital Twin and ADX, enabling the identification of pumps likely to fail and the estimation of their remaining useful life.

Recommendation Manager

XMPRO Recommendations are advanced event alerts that combine alerts, actions, and monitoring. You can create recommendations based on business rules and AI logic to recommend the best next actions to take when a certain event happens. You can also monitor the actions against the outcomes they create to continuously improve your decision-making.

Figure 1. Sub-Optimal Wind Direction Recommendation

This recommendation for wind turbine WT-01 identifies a suboptimal wind direction, indicating a misalignment detected in wind direction. The event data includes the current timestamp, power generation (2085 units), generation percentage (0.17%), wind direction (89.8 degrees), wind speed (7.1 m/s), and yaw (70.8 degrees). Users can add notes, assign the recommendation, share it, and create a work request with special instructions. The system tracks whether the recommendation solved the problem and provides options to mark it as a false positive or resolved. This setup ensures prompt response to wind direction misalignment issues, optimizing turbine performance and efficiency.

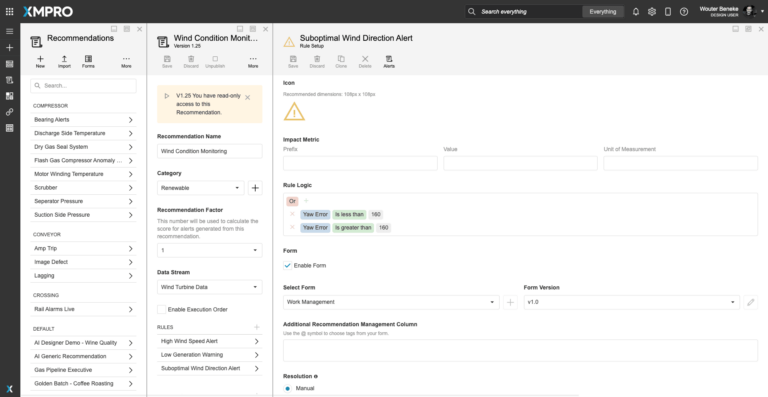

Figure 2. Configure With Granular Rule Logic

This suboptimal wind direction alert configuration allows users to set up granular rule logic for monitoring wind turbine conditions. The interface enables selecting metrics such as yaw error and setting specific thresholds to trigger alerts. Users can categorize recommendations, enable execution order, and auto-escalate critical issues.

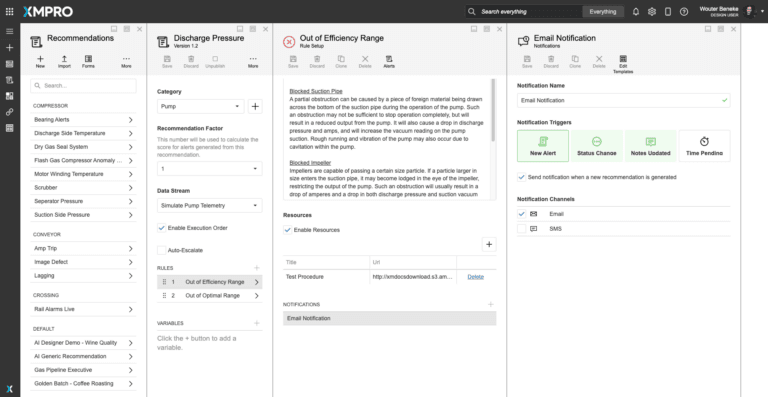

Figure 3. Close The Loop On Event Response

Closing the loop on event response, the system can take various actions, including sending email and SMS notifications for new recommendations, status changes, note updates, and pending times. Additionally, it can automatically create work orders, send information to ERPs, and execute other predefined actions, ensuring comprehensive monitoring and immediate response to pump issues with detailed guidance and timely alerts.

XMPro App Designer

The XMPro App Designer is a no code event intelligence application development platform. It enables Subject Matter Experts (SMEs) to create and deploy real-time intelligent digital twins without programming. This means that SMEs can build apps in days or weeks without further overloading IT, enabling your organization to accelerate and scale your digital transformation.

Figure 1. Real-Time Multi-Location Windfarm Overview Dashboard

This advanced dashboard is meticulously crafted for operators managing multiple windfarms, offering a comprehensive and unified view of wind turbine performance across various locations. It features an interactive map that dynamically updates with the operational status of different windfarms, providing a clear visual representation of their performance efficiency and health. Each windfarm on the map is marked with a color-coded status icon, indicating its current operational state, including active status and any alerts or error messages related to performance optimization or maintenance needs.

Overview of Windfarm Asset Health:

The dashboard displays the overall performance status of wind turbines across all locations, highlighting areas with potential efficiency issues or optimization opportunities. It includes critical alerts such as suboptimal wind direction alignment, blade pitch adjustments, and gearbox efficiency, pertinent to each specific windfarm.

Performance Optimization Alerts:

Leveraging data from integrated sensors and advanced analytics, the dashboard provides real-time insights into optimization opportunities for each windfarm. It highlights turbines requiring adjustments for issues like wind direction misalignment or blade pitch inefficiencies, tailored to the unique environmental conditions of each location.

Maintenance Planning and Scheduling:

A detailed graph tracks maintenance and performance optimization requirements across all windfarms. It prioritizes turbines based on their needs for maintenance or performance adjustments, facilitating efficient and proactive scheduling across multiple locations.

Drill-Down Capability for In-Depth Analysis:

Users can delve into specific windfarms for detailed information, including historical performance data, recent maintenance activities, and predictive maintenance recommendations. This level of detail enables targeted actions based on the system’s predictive analytics, tailored for each windfarm’s unique operational context.

Customizable Alerts and Recommendations:

The dashboard highlights active recommendations generated by the system’s smart rule logic and machine learning algorithms. This includes suggestions for enhancing turbine performance specific to each windfarm, addressing localized issues such as gearbox oil viscosity or blade wear.

Overall Asset Status Summary:

At the bottom of the screen, there’s a summary of the status of different assets, including the number of active and inactive turbines across various windfarms, providing a quick snapshot of the entire windfarm portfolio.

Search Functionality:

A search bar at the top allows users to search for specific data across the platform, enhancing the ease of navigating through information from multiple windfarms.

This Real-Time Multi-Location Windfarm Overview Dashboard is an indispensable tool for operators, enabling them to effectively monitor and optimize the performance of turbines across different windfarms. By providing real-time data, predictive insights, and actionable recommendations, it ensures informed decision-making and enhances the operational efficiency and energy output of wind turbines at each location.

Figure 2a. Real-Time Wind Farm Performance Management View

This XMPro digital dashboard, designed for Wind Farm Management, equips operators with essential tools for optimizing turbine operations and enhancing overall efficiency.

Immediate Energy Output Assessment:

The real-time power gauge showing current power generation in megawatts (MW) is crucial for assessing the farm’s immediate energy output. This feature allows operators to quickly identify any deviations from expected performance levels, which is key to maintaining optimal energy production.

Long-Term Performance Analysis:

The historical power chart displaying monthly power output data enables operators to analyze long-term performance trends. This insight is vital for strategic planning, identifying underperformance periods, and making informed decisions about maintenance and operational adjustments. Data Range: Monthly data from May to April.

Targeted Turbine Maintenance and Optimization:

The status table for individual wind turbines provides detailed information on each turbine’s status, power output, and performance. This targeted approach helps in pinpointing turbines that require maintenance or optimization, directly influencing the overall efficiency and reliability of the wind farm. Details: Asset name, status, power output, and performance percentage.

Visual Management of Wind Farm Operations:

The farm overview visualization offers a geographical representation of the wind farm, with clear indicators for each turbine’s status. This visual management tool is essential for large-scale operations, enabling quick identification and prioritization of turbines for performance optimization or maintenance.

Optimization Based on Wind Conditions:

The wind details section, showing real-time wind speed and direction, is critical for adjusting turbine operations to maximize energy capture. This real-time data ensures turbines are optimally aligned with current wind conditions, enhancing energy production efficiency. Metrics: Wind speed (m/s) and direction (degrees).

Proactive Maintenance and Performance Alerts:

The dashboard’s recommendations and alerts section provides actionable insights for proactive maintenance and performance optimization. These alerts address issues that can significantly impact energy output, ensuring timely interventions for optimal turbine performance.

Enhanced Operational Efficiency and User Experience:

The user-friendly interface with easy navigation and quick access to various functionalities enhances operational efficiency. This feature allows operators to manage complex wind farm operations effectively, ensuring optimal performance and maintenance scheduling. The Real-Time Wind Farm Performance Management Dashboard is a comprehensive tool that provides wind farm operators with the necessary data and insights for optimizing turbine performance and overall wind farm efficiency. Its combination of real-time monitoring, historical analysis, and actionable recommendations plays a crucial role in enhancing the operational efficiency and energy output of wind farms.

Figure 2.b Real-Time Wind Farm Performance Management View – Individual Wind Turbine

This XMPro dashboard view provides a detailed perspective on individual wind turbines within a wind farm, enhancing the ability to monitor and optimize each turbine’s performance.

Figure 3. Asset Analysis View – Wind Turbine WT-10 Health

This Asset Analysis View on the XMPro dashboard offers detailed insights into a specific wind turbine within a renewable energy system, focusing on turbine WT-10.

Comprehensive Production and Performance Data:

The left section of the dashboard displays crucial production data for WT-10, including kilowatt-hours (2107 kWh), average power (1837 kW), and performance (63.7%). A green line graph illustrates the power output fluctuation over time, providing a visual representation of the turbine’s energy production efficiency. This data is essential for assessing the turbine’s current output and identifying trends or deviations in performance.

Detailed Turbine Information:

Below the production data, detailed information about WT-10 is listed, including turbine ID, wind farm location (West Rock), total power generated (7.8 GWh), operational hours (5345), and the turbine model (GE Haliade-X 14 MW). Geographical coordinates are also provided. This comprehensive profile is vital for understanding the turbine’s operational context and history, aiding in maintenance planning and performance analysis.

Weather Forecast for Operational Planning:

A 3-day weather forecast presents predictions for wind top speed and temperature highs, along with expected weather conditions. This forecast is crucial for anticipating environmental factors that could impact turbine performance and planning appropriate operational responses.

Blade Damage Analysis:

A detailed table outlines the damage to the turbine’s blades, including blade side, severity, damage type (LE Erosion), and the affected area in square meters. This information is critical for prioritizing maintenance activities and addressing blade health, which directly impacts turbine efficiency.

Interactive 3D Turbine Visualization:

The central 3D visualization of WT-10 highlights different parts, such as the rotor hub, and shows an alert symbol indicating issues. This interactive model allows for a deeper understanding of the turbine’s condition and aids in identifying areas requiring attention.

Wind Speed and Direction Monitoring:

On the right, a gauge displays the current wind speed (8.7 m/s) and direction (237°), along with an average wind speed indicator. Monitoring these conditions is essential for optimizing turbine alignment and settings to maximize energy capture.

Targeted Recommendations and Alerts:

Below the wind details, specific recommendations and alerts for WT-10 are listed, including high wind speed, suboptimal wind direction, and low wind speed warnings. These alerts, complete with timestamps, are key for proactive maintenance and operational adjustments.

User Interface and Navigation:

The dashboard includes a search function, user profile, and other interface icons for easy navigation and settings adjustments. This enhances the user experience, allowing for efficient management of turbine data and settings.

This Asset Analysis View for Wind Turbine WT-10 on the XMPro dashboard provides a specialized and comprehensive analysis of the turbine’s performance, condition, and environmental factors. It is an invaluable tool for maintenance planning, operational decision-making, and optimizing the turbine’s energy output and efficiency.

XMPro AI (Optional)

Experience the transformative power of XMPro’s Intelligent Business Operations Suite (iBOS) – Featuring comprehensive AI capabilities, XMPro iBOS helps to significantly increase product yield, drastically reduce downtime, and ultimately eliminate unexpected business events.

Use XMPro Blueprints for Quick Time To Value

Easily import Blueprints, Accelerators and Patterns into your environment, providing a starting point for configuring your own solutions.

Why XMPro iBOS For Intelligent Multi-Location Winf Farm Management?

XMPro’s Intelligent Business Operations Suite (iBOS) offers several unique solutions for optimizing the performance of wind turbines, particularly in the context of the Wind Turbine Performance Optimization use case. Here’s how XMPro iBOS effectively addresses this challenge:

Advanced Intelligent Digital Twin Modeling:

XMPro iBOS creates sophisticated digital twins of individual wind turbines, providing a virtual representation that mirrors their real-world conditions. This enables detailed analysis and simulation of turbine performance under various environmental and operational scenarios.

Advanced Sensor Data Integration & Transformation:

The suite integrates real-time data from various sensors on the wind turbines, such as wind speed, direction, temperature, and turbine operational metrics. This integration allows for comprehensive monitoring and analysis of turbine performance, identifying areas for optimization.

Predictive Analytics for Performance Enhancement:

Utilizing advanced predictive analytics, XMPro iBOS can forecast potential performance issues and identify optimal operational settings for each turbine. This predictive approach enables proactive adjustments to maximize efficiency and energy output.

Maintenance Scheduling Optimization:

By analyzing performance data, XMPro iBOS helps optimize maintenance schedules, shifting from a reactive to a predictive maintenance approach. This reduces downtime and extends the lifespan of turbine components.

Real-Time Monitoring and Predictive Alerting:

The platform can generate automated recommendations for adjusting turbine settings, such as blade pitch or rotation speed, based on real-time data and predictive insights. This automation ensures turbines operate at their peak efficiency.

Customizable and Interactive Dashboards:

XMPro iDTS features customizable dashboards that provide real-time insights into turbine performance. These dashboards are interactive, allowing operators to drill down into specific aspects of turbine operation, such as power output, rotor speed, and blade health.

Scalability and Flexibility – Start Small, Scale Fast:

XMPro iBOS offers scalable and flexible solutions, allowing wind farms to start small and expand as needed. Its modular design ensures easy integration and adaptability, facilitating quick deployment and future-proof scalability.

Enhanced Safety & Operational Efficiency:

he suite enhances operational safety by predicting and mitigating potential risks associated with turbine operation. It also improves overall operational efficiency by ensuring turbines operate within optimal parameters.

XMPro Blueprints – Quick Time to Value:

XMPro Blueprints offer a rapid path to value realization for wind farms. These pre-configured templates are designed for quick implementation, incorporating best practices and industry standards.

In summary, XMPro iBOS addresses the Wind Turbine Performance Optimization use case by providing a comprehensive, real-time, predictive, and integrated solution. Its capabilities in digital twin technology, advanced data integration, predictive analytics, and interactive dashboards make it a powerful tool for enhancing the performance, safety, and efficiency of wind turbines.

Not Sure How To Get Started?

No matter where you are on your digital transformation journey, the expert team at XMPro can help guide you every step of the way - We have helped clients successfully implement and deploy projects with Over 10x ROI in only a matter of weeks!

Request a free online consultation for your business problem.

"*" indicates required fields