Documentation

Get detailed guidance on platform features

Introduction

In large-scale mining operations, conveyor belts are critical for transporting materials efficiently. Long conveyors, in particular, face significant challenges due to their extended length and continuous operation. Ensuring their optimal performance and preventing unexpected failures is essential for maintaining productivity and minimizing downtime. XMPro’s Long Conveyor Condition Monitoring & Predictive Maintenance Solution offers comprehensive monitoring and predictive maintenance capabilities to address these challenges.

Typical Problems Faced:

XMPro’s Long Conveyor Condition Monitoring & Predictive Maintenance Solution leverages real-time data integration, advanced analytics, and predictive maintenance to enhance the reliability and efficiency of conveyor systems.

By adopting a data-centric approach, it substantially increases the accuracy, efficiency, and scalability of conveyor management, which is crucial for maintaining stringent operational and safety standards.

Real-Time Monitoring and Control: XMPro’s solution provides a centralized platform for real-time monitoring and control of conveyor systems, offering insights into operational parameters such as speed, load, and vibration.

Predictive Analytics for Maintenance Optimization: The system employs advanced predictive analytics to forecast potential failures and maintenance needs. By leveraging machine learning models, it can predict when components are likely to fail and recommend timely interventions.

Digital Twin Technology: XMPro’s Intelligent Digital Twin Suite (iDTS) creates detailed digital replicas of conveyor systems. These digital twins simulate real-world conditions and enable scenario planning, optimizing maintenance schedules and operational strategies without disrupting actual operations.

Automated Maintenance Scheduling: The platform automates maintenance scheduling based on real-time data and predictive analytics, ensuring that maintenance activities are conducted just in time. This approach reduces downtime and operational costs by preventing unnecessary maintenance interventions and addressing issues before they escalate.

Integration with IoT and Data Sources: XMPro integrates data from various IoT devices and operational systems, providing a comprehensive view of equipment health and performance. This integration facilitates the continuous collection and analysis of data, enhancing the accuracy of predictive models.

Customizable Dashboards and Reporting: XMPro offers customizable dashboards that provide actionable insights and detailed reports on conveyor system performance. These dashboards help in tracking key performance indicators (KPIs), compliance, and operational efficiency.

Enhanced Safety and Risk Management: The solution includes features for operational safety intelligence, highlighting potential hazards and recommending control measures. It helps in mitigating risks associated with equipment failures and ensuring a safer working environment.

Scalability and Flexibility: Designed to scale with the needs of the mining industry, XMPro’s solution supports the expansion of operations while maintaining the flexibility required to adapt to new challenges and opportunities.

By implementing XMPro’s Long Conveyor Condition Monitoring & Predictive Maintenance Solution, mining operations can achieve significant improvements in efficiency, reliability, and cost savings. The use of predictive maintenance principles ensures that maintenance is conducted based on actual equipment conditions, leading to reduced downtime, extended equipment lifespan, and enhanced overall operational performance

XMPRO’s Data Stream Designer lets you visually design the data flow and orchestration for your real-time applications. Our drag & drop connectors make it easy to bring in real-time data from a variety of sources, add contextual data from systems like EAM, apply native and third-party analytics and initiate actions based on events in your data.

Figure 2: Conveyor Health Condition Monitoring Data Stream

This conveyor condition monitoring data stream ingests telemetry data from all conveyors, cleans it, and broadcasts it to various endpoints. The data is contextualized with information about the conveyor make, model, and operational context. It then undergoes several transformations and functions: the data is cleaned up for recommendations, rounded for precision, and filtered to exclude irrelevant belts. The processed data is used to view asset data and evaluate failure recommendation rules. This comprehensive data flow ensures precise, efficient, and actionable insights into the health of the conveyor system, enabling proactive maintenance and enhanced operational reliability.

XMPRO Recommendations are advanced event alerts that combine alerts, actions, and monitoring. You can create recommendations based on business rules and AI logic to recommend the best next actions to take when a certain event happens. You can also monitor the actions against the outcomes they create to continuously improve your decision-making.

Figure 1. Amperage Exceeded Threshold Recommendation

This recommendation identifies an issue with the amperage exceeding the defined threshold, indicating a differential greater than 30%. The event data includes details such as drive amps, reading number, timestamp, health score, conveyor speed, and asset number. Users can add notes, mark the recommendation as solved or a false positive, assign the recommendation, share it, and create a work request with special instructions if necessary. This structured approach ensures that potential issues are efficiently addressed and resolved to maintain optimal conveyor performance.

Figure 2. Configure with Granular Rule Logic

This amperage threshold recommendation configuration allows users to set up granular rule logic for monitoring conveyor conditions. The interface enables selecting metrics such as drive amps and setting specific thresholds to trigger alerts. Users can categorize recommendations, enable execution order, and auto-escalate critical issues. The configuration includes setting impact metrics, defining rule logic with conditions (e.g., drive amps greater than 50 but less than 70), and linking to forms for work requests. This detailed setup ensures precise monitoring and timely intervention for maintaining conveyor system efficiency.

The XMPro App Designer is a no code event intelligence application development platform. It enables Subject Matter Experts (SMEs) to create and deploy real-time intelligent digital twins without programming. This means that SMEs can build apps in days or weeks without further overloading IT, enabling your organization to accelerate and scale your digital transformation.

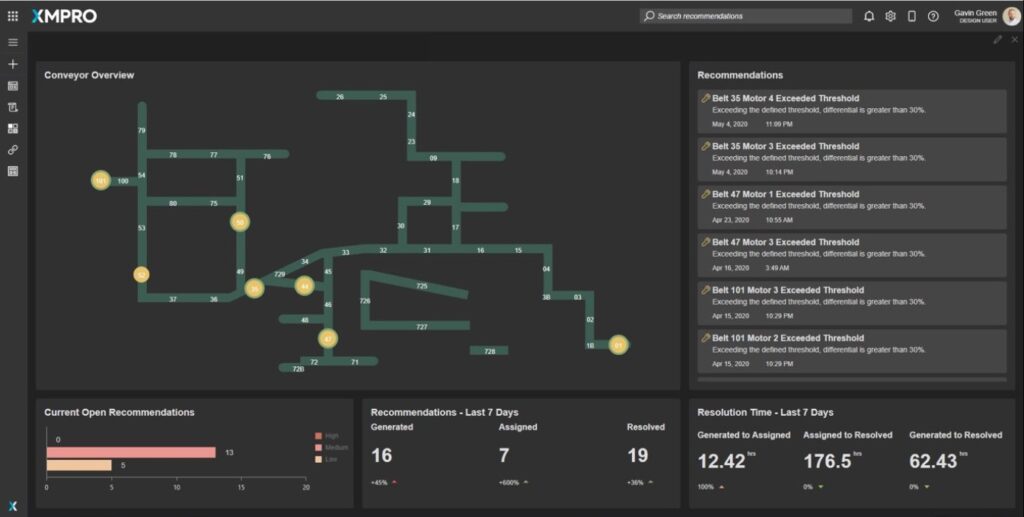

Figure 1: Real-Time Mine Conveyor Overview

The Real-Time Mine Conveyor Overview dashboard provides a comprehensive visualization of the entire conveyor system, enabling operators to monitor and manage conveyor operations effectively.

Key Dashboard Features:

Conveyor Layout Visualization:

Predictive Maintenance Alerts:

Current Open Recommendations:

Recommendations and Resolution Metrics:

Resolution Time Analysis:

Benefits for the Client:

This comprehensive overview enables operators and maintenance teams to monitor conveyor performance effectively, identify potential issues early, and take corrective actions to maintain high operational standards and equipment reliability.

Figure 2: Mainline Conveyor #16

The Mainline Conveyor #16 dashboard offers an in-depth analysis of the primary and secondary motors, providing real-time data and predictive maintenance insights to ensure optimal performance and prevent unexpected failures.

Key Dashboard Features: Conveyor Details:

Primary and Secondary Motor Differentials:

Motor Performance Metrics:

Predictive Maintenance Alerts:

Recommendations:

Work Request History:

Value for the Client:

This detailed analysis and predictive maintenance approach ensure that Mainline Conveyor #16 operates efficiently and reliably, minimizing downtime and maintenance costs while maximizing productivity.

Figure 3: Conveyor Belt #22637

The Conveyor Belt #22637 dashboard provides a comprehensive overview of the operational status and performance metrics for Conveyor Belt #22637, offering real-time data and predictive maintenance insights to optimize performance and prevent unexpected failures.

Key Dashboard Features: Differentials:

Tonnage:

Amperage:

Primary and Secondary Draw:

Real-time Alerts and Recommendations:

Current Open Recommendations:

Work Request History:

Value for the Client:

By leveraging the real-time data and predictive maintenance capabilities of the XMPro Conveyor Belt #22637 dashboard, mining operations can achieve significant improvements in efficiency, reliability, and cost savings. This comprehensive approach ensures that maintenance is conducted based on actual equipment conditions, leading to reduced downtime, extended equipment lifespan, and enhanced overall operational performance.

Figure 4: Real-Time Mine Health Overview The Real-Time Mine Health Overview dashboard provides a holistic view of the mine’s operational health, highlighting key metrics, alerts, and the status of various components. This dashboard is essential for maintaining overall mine efficiency and safety.

Key Dashboard Features: Conveyors with Open Alerts:

Current Work Order Status:

Value Tracking:

Metrics for the Last 4 Weeks:

Borers Health Overview:

Resolution Time Analysis:

Value for the Client:

By utilizing the Real-Time Mine Health Overview dashboard, mining operations can achieve significant improvements in efficiency, reliability, and safety. The combination of real-time data, predictive maintenance insights, and comprehensive visualization ensures that all aspects of the mine’s operations are closely monitored and optimized.

Experience the transformative power of XMPro’s Intelligent Business Operations Suite (iBOS) – Featuring comprehensive AI capabilities, XMPro iBOS helps to significantly increase product yield, drastically reduce downtime, and ultimately eliminate unexpected business events.

In order to maximize underground mining operations, the underground conveyor system, a frequent cause of unplanned downtime, needed to reduce its downtime by 30% as an initial target for a predictive maintenance solution

XMPro actively monitors 52 conveyors (spanning over 80+km) in real time, predicting fluid coupling and lagging failures with prescriptive recommendations.

Within five months, the solution identified a potential saving of 184 hours of borer downtime, equating to 44k product tonnes. Exceeding the target, the solution achieved over a 80% reduction in downtime for fluid coupling failures. It now monitors multiple asset types across several mines

XMPro’s Intelligent Business Operations Suite (iBOS) is specifically engineered to address the complexities of monitoring and maintaining long conveyor systems in mining operations. Here are the key reasons why XMPro iBOS stands out as the ideal solution:

XMPro iBOS creates sophisticated digital twins for each conveyor system, providing a virtual representation that mirrors the real-world conditions of the conveyors. This feature enables detailed analysis and simulation of conveyor performance under various operational scenarios, crucial for managing extensive conveyor networks in mining operations.

The suite integrates real-time data from a variety of sensors on conveyors, including speed, load, vibration, and temperature. This comprehensive monitoring allows for the identification of optimization areas across the conveyor system, ensuring consistent performance and efficiency.

Utilizing advanced predictive analytics, XMPro iBOS forecasts potential performance issues and identifies optimal operational settings for each conveyor segment, considering the unique operational conditions. This predictive approach enables proactive adjustments, maximizing efficiency and minimizing downtime.

XMPro iBOS analyzes performance data to optimize maintenance schedules, transitioning from a reactive to a predictive maintenance approach. This strategy reduces downtime and extends the lifespan of conveyor components, which is particularly beneficial for managing maintenance resources efficiently.

The platform generates automated recommendations for adjusting conveyor settings based on real-time data and predictive insights. This feature ensures that conveyors operate at peak efficiency, with minimal manual intervention.

XMPro iBOS features configurable dashboards that provide real-time insights into the performance of conveyor systems. These dashboards are interactive, allowing operators to drill down into specific aspects of conveyor operation, facilitating centralized control and decision-making.

XMPro iBOS offers scalable and flexible solutions, ideal for conveyor systems of varying sizes and complexities. Its modular design ensures easy integration and adaptability, allowing for quick deployment and scalability as the conveyor network expands.

The suite enhances operational safety by predicting and mitigating potential risks associated with conveyor operation. It improves overall operational efficiency by ensuring conveyors operate within optimal parameters.

XMPro Blueprints provide a rapid path to value realization for mining operations. These pre-configured templates are designed for quick implementation, incorporating best practices and industry standards.

By implementing XMPro iBOS for Long Conveyor Condition Monitoring & Predictive Maintenance, mining operations can achieve significant improvements in efficiency, reliability, and safety. The combination of advanced predictive maintenance capabilities, comprehensive digital twin technology, and real-time data integration makes XMPro iBOS the ideal solution for optimizing conveyor system performance and enhancing overall operational effectiveness.

"*" indicates required fields