Documentation

Get detailed guidance on platform features

Achieving a high First Pass Yield is crucial for manufacturing efficiency and product quality. However, manufacturers often face challenges that impact FPY:

XMPro’s solution to improve First Pass Yield utilizes XMPro iDTS to offer a data-driven and proactive approach to enhancing manufacturing processes and product quality.

Key Metrics Monitored:

XMPro iDTS offers specialized solutions to address the challenges associated with improving First Pass Yield (FPY) in manufacturing processes. Here’s how XMPro iDTS can be specifically applied to enhance the FPY Improvement Solution:

Digital Twin for Manufacturing Processes:

XMPro iDTS can create a digital twin of the manufacturing process, providing a virtual representation that mirrors the physical production line. This allows for real-time simulation, analysis, and optimization of the manufacturing process, enabling a deeper understanding of how various factors affect FPY.

Predictive Analytics for Quality Control:

Utilizing advanced analytics and machine learning, XMPro iDTS can analyze data from the manufacturing process to predict potential quality issues before they occur. This predictive approach allows for proactive adjustments to the process, reducing defects and increasing FPY.

Real-Time Monitoring of Process Parameters:

XMPro iDTS can continuously monitor critical process parameters such as temperature, pressure, speed, and machine performance. By analyzing this data in real-time, the system can identify deviations from optimal conditions and recommend adjustments to maintain product quality.

Integration with Quality Management Systems:

XMPro iDTS can integrate with existing quality management systems to provide a comprehensive view of quality control measures and outcomes. This integration is crucial for identifying areas for improvement and implementing effective quality control strategies.

Automated Alerts and Recommendations:

XMPro iDTS can automate the generation of alerts and recommendations when potential quality issues are detected. This feature ensures timely interventions, reducing the rate of rework or scrap and maintaining high FPY.

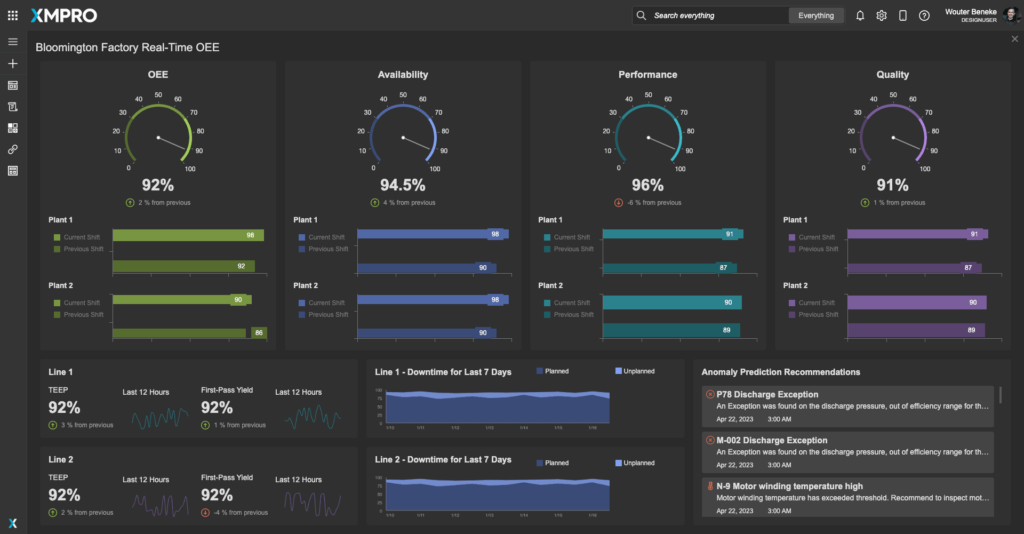

Customizable Dashboards and Reporting:

XMPro iDTS provides advanced data visualization tools and customizable dashboards, which are essential for monitoring and analyzing manufacturing processes. These tools enable different stakeholders to access relevant information, understand trends, and make informed decisions quickly.

Scalability and Flexibility:

XMPro iDTS is scalable, meaning it can be expanded to accommodate additional manufacturing lines, processes, or data sources as operational needs evolve.

Material Quality Analysis:

By monitoring and analyzing the quality of raw materials, XMPro iDTS helps ensure that only materials meeting the required standards are used in the manufacturing process, further contributing to higher FPY.

In summary, XMPro iDTS addresses the unique challenges in improving First Pass Yield by providing a comprehensive, real-time, predictive, and integrated solution. Its use of digital twin technology, combined with advanced analytics, automated guidance, and effective data visualization, makes it a powerful tool for optimizing manufacturing processes and enhancing product quality.